The Intersection of 3D Printing and CNC Machining in Oilfield Part Production

Modern oilfield production demands extreme precision and rapid turnaround times. Today, the 3D printing and CNC machining intersection is revolutionizing how we manufacture critical downhole components. By combining additive speed with subtractive accuracy, companies can produce complex geometries that were once impossible to create.

This hybrid approach allows us to reduce material waste and slash lead times. As the industry evolves, integrating 3D printing and CNC machining ensures that parts meet rigorous API standards while pushing the boundaries of engineering innovation.

Understanding the Two Powerhouses

To appreciate the intersection of these technologies, we must first look at what each brings to the table. In the past, these were seen as rival methods. Today, they are viewed as a "dream team" for engineering.

3D Printing (Additive Manufacturing)

In the oilfield context, this usually refers to Metal Additive Manufacturing. Using techniques like Powder Bed Fusion or Directed Energy Deposition, a laser melts metal powder layer-by-layer to build a part.

- The Advantage: It can create hollow structures, internal cooling channels, and complex lattices that a drill bit simply cannot reach.

- The Limitation: Parts straight out of a printer (often called "near-net-shape") have a grainy surface finish and lack the microscopic precision required for high-pressure seals.

CNC Machining (Subtractive Manufacturing)

CNC machining is the bedrock of the oil industry. It involves taking a solid block (billet) or a casting and carving away material using high-speed rotating tools.

- The Advantage: Unbeatable precision. We can achieve tolerances within microns and create mirror-like surface finishes essential for O-ring seats and threaded connections.

- The Limitation: It can be wasteful (turning a large expensive block into a small part) and is limited by "tool access"—if a tool can't reach it, it can't cut it.

Why the Oilfield Needs Both Technologies

The oil and gas environment is one of the most punishing on earth. Equipment must survive "HPHT" (High Pressure, High Temperature) conditions, corrosive saltwater, and abrasive sands.

Reducing Expensive Downtime

In offshore drilling, a single day of downtime can cost hundreds of thousands of dollars. Traditional forging and machining of custom parts can take months. By using 3D printing and CNC machining together, we can print a "blank" in days and finish-machine it in hours, getting the rig back to work weeks ahead of schedule.

Optimized Flow Dynamics

Many oilfield parts, like manifold inserts or centrifugal pump impellers, rely on efficient fluid flow. 3D printing allows engineers to design internal curves that reduce turbulence and erosion. Once printed, CNC machining is used to ensure the mounting points and shafts are perfectly balanced and sized.

Key Applications in Oilfield Part Production

Where exactly does this "Intersection" happen in the field? Here are four critical areas:

1. Rotary Steering Systems (RSS)

RSS tools are packed with sensors and fluid passages. Traditionally, these passages had to be drilled in straight lines and plugged. With additive manufacturing, we can "print" the fluid paths in a smooth, continuous spiral. We then use CNC machining to create the high-precision threads that connect these tools to the rest of the drill string.

2. Custom Stabilizers and Reamers

Every wellbore is different. Sometimes a driller needs a stabilizer with a specific blade geometry for a unique rock formation. We can print the complex blade shapes—which would be incredibly difficult to mill from a solid block—and then use our CNC lathes to ensure the tool is perfectly concentric.

3. High-Performance Valve Trim

Valves in the oilfield often face "cavitation" (bubbles forming and collapsing, which eats away at metal). Using 3D printing, we can create "tortuous path" valve trims that manage pressure drops more gracefully. CNC machining then ensures the valve seat is perfectly flat to prevent leaks at 15,000 PSI.

4. Obsolete Part Recovery

Many oil rigs operate with equipment that is 30 or 40 years old. If a part breaks and the original manufacturer is out of business, what do you do? We can 3D scan the broken part, print a new one in a modern superalloy, and use CNC machining to bring it back to original specifications.

The Hybrid Workflow: Step-by-Step

How do we actually execute a project involving 3D printing and CNC machining? It is a highly controlled process.

Phase 1: Additive Foundation

We start with a digital CAD model. The part is printed with "extra meat" (additional material) on any surface that requires a high-precision finish. This is the "Near-Net-Shape."

Phase 2: Thermal Stress Relief

Metal printing involves intense heat. As the metal cools, internal stresses can build up. Before we put the part on a CNC machine, it must go through a heat-treatment furnace to stabilize the metal and ensure it won't warp during the cutting process.

Phase 3: CNC Precision Finishing

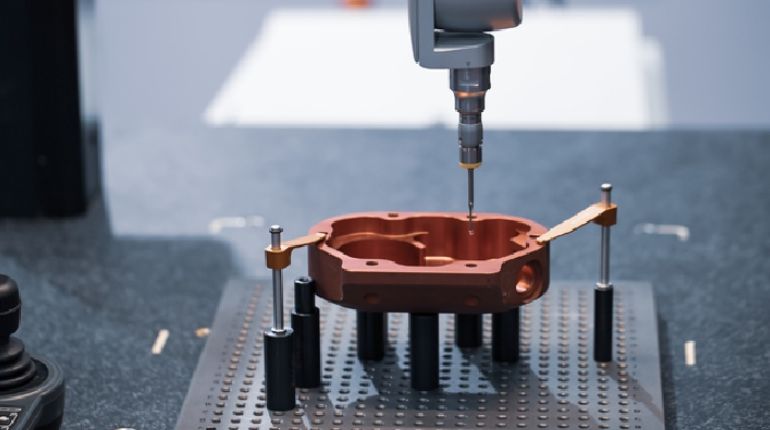

This is where Standard Machining’s expertise shines. We mount the printed part into our CNC centers. We mill the sealing faces, tap the bolt holes, and cut the API-standard threads. This phase turns a "printed object" into a "mechanical component."

Phase 4: Inspection and Validation

Oilfield parts cannot fail. We use Coordinate Measuring Machines (CMM) to verify dimensions and Non-Destructive Testing (NDT) to ensure there are no microscopic cracks in the printed structure.

Overcoming Common Challenges

It isn't as simple as "print and cut." There are hurdles to clear:

- Material Integrity: Printed metal has a different grain structure than forged metal. Engineers must account for this in their safety factors.

- Workholding: 3D printed parts often have irregular shapes, making them hard to "grip" in a standard CNC vise. We often have to design and machine custom "fixtures" just to hold the printed part for finishing.

- Cost: While it saves time, the raw powder for metal 3D printing is expensive. This method is best for complex, low-volume parts rather than thousands of simple bolts.

Future Trends: The Road to "Smart" Oilfields

The intersection of 3D printing and CNC machining is only getting tighter. We are seeing the rise of "All-in-One" hybrid machines that can add metal and then immediately switch to a milling tool to cut it back, all in the same chamber.

Furthermore, "Digital Warehousing" is becoming a reality. Instead of keeping millions of dollars of iron sitting in a warehouse in Houston or Dubai, companies keep a "digital twin." When a part is needed in the North Sea, the file is sent to a local shop with 3D printing and CNC capabilities, and the part is made on-demand.

Conclusion

The synergy between 3D printing and CNC machining is more than just a trend; it is the future of resilient oilfield infrastructure. By leveraging both technologies, manufacturers can deliver high-performance parts that withstand the harshest environments with unmatched precision and speed.

At Standard Machining, we specialize in the high-tolerance finishing required to bring your most complex designs to life. Contact our team today to see how our expertise can optimize your next project and keep your operations running smoothly.