Stainless Steel 17-4PH Vs 301: What's The Difference?

Stainless steel is an incredibly popular material, used for a variety of applications in many industries around the world.

Did you know that over 60% of all stainless steel produced each year is grade 304?

It's no surprise then, that two other common grades, 17-4PH and 301 are often compared to one another.

In this article, we will dive deep into the differences between these two stainless steel alloys and discuss their various strengths and weaknesses.

We'll also look at the different applications they are used for as well as any cost considerations when it comes to selecting the right alloy for your project.

By the end of this article, you will have a better understanding of which alloy will best suit your needs and why.

So let's get started!

Overview of Stainless Steel Alloys

You may have heard of various alloys used for different purposes, but do you know the difference between 17-4ph and 301? Stainless steel alloys are versatile materials used in many applications.

Two commonly used alloys are 17-4ph and 301. Understanding the differences between them and their unique properties can help you choose the right material.

17-4ph is an age-hardened alloy that provides high strength and hardness. It has relatively low compositions of nickel, copper, chromium, and other elements. Additionally, it contains 4% phosphorus which helps increase its corrosion resistance compared to other stainless steels.

On the other hand, 301 stainless steel has higher levels of nickel and chromium than 17-4ph. It is a better choice for applications that require increased corrosion resistance at higher temperatures or with aggressive chemicals. It's also slightly softer than 17-4ph due to its lower phosphorus content.

Comparison of 17-4PH and 301 Alloys

You've likely heard of 17-4PH and 301 alloys, but do you know what sets them apart? Let's explore the key contrast between these two metals - don't be afraid to dive in headfirst!

The primary difference between 17-4PH and 301 is their composition. 17-4PH is an iron-chromium-nickel alloy that contains 17% chromium, 4% nickel, 1% manganese, and small amounts of carbon and copper.

On the other hand, 301 stainless steel contains chromium (17–19%), nickel (6–8%), and an increased amount of carbon (0.15%). This makes it less resistant to corrosion than its counterpart.

In addition to different compositions, the two alloys have different mechanical properties as well. 17-4PH has a higher tensile strength than 301 stainless steel; however, it also has a lower ductility making it more brittle.

By comparison, 301 stainless steel has superior ductility which makes it suitable for applications requiring good formability such as stamping processes. Therefore, depending on your desired application - whether it's strength or formability - either one might be right for you!

Pros and Cons of 17-4PH and 301

Discovering the advantages and disadvantages of 17-4PH and 301 alloys can help you decide which one is right for your application.

17-4PH alloy offers superior corrosion resistance in a wide variety of environments, making it ideal for applications that require strength and durability. It also has low thermal expansion, making it useful for components that need to maintain their shape at high temperatures. However, its higher cost may be prohibitive in some cases.

On the other hand, 301 alloy is much more economical than 17-4PH but still provides good corrosion resistance and strength. However, its lower heat resistance means that it's not suitable for use in certain types of manufacturing processes or equipment. Additionally, its higher magnetism makes it inappropriate for use near sensitive electronic components.

Ultimately, understanding the pros and cons of each material helps you make an informed decision about which one best suits your needs.

Applications for 17-4PH and 301

You may be wondering what kind of applications 17-4PH and 301 stainless steel are used for.

Both materials can be found in medical devices as well as aerospace components.

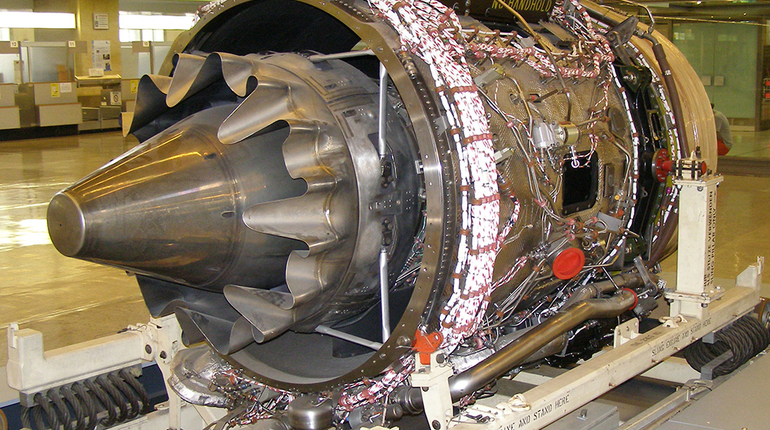

17-4PH is a precipitation hardening type of stainless steel that's incredibly strong, making it an ideal choice for manufacturing parts that require high strength and corrosion resistance. This is especially true for those used in the aerospace industry.

On the other hand, 301 stainless steel is known for its ductility and malleability, which makes it popularly used in medical devices.

Medical Devices

Crafting medical devices requires careful consideration of the benefits and drawbacks of using 17-4ph or 301 stainless steel. Both alloys offer a range of advantages depending on how they are treated, yet both come with unique considerations that must be taken into account.

17-4PH is usually chosen for its strength and superior corrosion resistance, while 301 is preferred due to its malleability and formability. When it comes to medical device applications, these qualities can make a difference in their effectiveness.

17-4PH's high strength makes it ideal for components that require maximum durability or where weight savings are essential, such as implants and prosthetics. It also offers excellent corrosion resistance due to its high chromium content, making it suitable for use in instruments exposed to harsh conditions such as saline solutions or other body fluids.

On the other hand, 301 stainless steel offers increased malleability which allows parts to be formed into complex shapes without sacrificing structural integrity. This makes it ideal for surgical instruments that need intricate contours or those that require precision cutting ability such as scalpels and dental tools.

Ultimately, choosing between these two alloys depends upon the specific needs of each application; both have important strengths and potential weaknesses, so understanding the requirements of your project is essential before selecting one over the other.

Aerospace Components

Now let's explore stainless steel 17-4ph and 301 in the aerospace industry. These materials are essential for creating parts that can withstand extreme pressures and temperatures of space exploration. Both 17-4ph and 301 have superior strength and durability, making them great choices for a variety of aerospace components.

17-4ph is ideal for machined parts like fasteners, fittings, gears, shafts, and structural components. It has high fatigue strength and corrosion resistance, and a higher tensile strength than 301. This makes it more suitable for components with complex geometries or requiring intricate details such as valves or actuators.

On the other hand, 301 provides excellent weldability along with great formability. It is perfect for parts like frames or housings where welding may be needed.

Cost Considerations

When it comes to cost, you'll want to weigh your options carefully. 17-4PH stainless steel is often more expensive than 301 stainless steel due to its higher nickel content and increased strength.

However, when considering the overall life cycle costs of a project, the price difference can be offset by fewer replacements or repairs needed over time. This makes 17-4PH stainless steel a great choice for projects where durability is key.

Alternatively, if cost is your number one priority then 301 may be the better option since it has lower initial costs with slightly lower performance in areas such as corrosion resistance and machinability.

Either way, it's important to consider all factors before making a decision so that you can get the best value for your money.

Heat Treatment of 17-4PH and 301

You need to consider the heat treatment process for 17-4PH and 301 stainless steels, as it can be the difference between success and failure in your project - think of it like a game of chess!

Depending on the form taken by 17-4PH or 301 stainless steel, the heating processes vary. For example, if you're working with flat bar material from either grade then a solution annealing heat treatment must first take place. This is where the material is heated to a temperature between 1900°F (1038°C) and 2050°F (1121°C).

After this has been done, you can then cool your material slowly in order to gain maximum mechanical properties. However, if you're dealing with pre-hardened materials from either grade then different processes are needed.

In this case, 17-4PH will require tempering at temperatures ranging from 400°F (204°C) to 600°F (316°C) whereas 301 requires higher temperatures of up to 900°F (482 °C). It's essential that these heat treatments are completed correctly or else they could lead to unexpected results in your finished product!

Conclusion

No matter the grade of stainless steel you're working with, it's essential to get your heat treatment process right - or else you could end up disappointed with your finished product!

When comparing 17-4PH and 301 stainless steels, there are distinct differences in their heat treatments. 17-4PH is a precipitation hardening steel that requires much higher temperatures than 301 for proper heat treatment. While the exact temperature range varies depending on the specific application, 17-4PH typically needs to be heated between 900°F and 1150°F for good results.

On the other hand, 301 is an austenitic stainless steel which should not be treated at temperatures above 1550°F as this can cause a reduction in its corrosion resistance properties.

Overall, when selecting a grade of stainless steel for your project, it's important to consider how each type responds to heat treatment. Fortunately, both 17-4PH and 301 are high quality materials that offer excellent performance across many applications – so whichever one you choose will serve you well if you take the time to get your heat treating process just right!