5 Challenges in CNC Machining Titanium

Titanium is a remarkable material. It is known for its high strength and low weight. However, machining it presents unique difficulties. This article explores the top 5 challenges in CNC machining titanium.

We will cover why titanium is hard to machine. You will learn about the main challenges. We also provide practical solutions. This will help you optimize your machining process for this unique metal.

Why is Titanium Hard to Machine?

Titanium's unique properties make it tough to machine. Its high strength and low thermal conductivity are key factors. The material tends to stick to cutting tools. This causes friction and excessive heat.

This heat does not dissipate easily. Instead, it concentrates in the cutting zone. This can lead to rapid tool wear. It also compromises the surface finish of the part. Understanding these traits is the first step to success.

5 Key Titanium Machining Challenges

Machining titanium requires skill and the right equipment. Let's look at the five main challenges you might face.

1. Poor Thermal Conductivity

Titanium does not conduct heat well. During machining, heat builds up in the tool and workpiece. This high temperature can cause the tool to wear out quickly. It can even lead to tool failure.

This heat concentration affects the part's integrity. It can cause dimensional inaccuracies. Managing heat is critical for successful titanium machining.

2. High Chemical Reactivity

Titanium is highly reactive at high temperatures. It can react with cutting tool materials. This leads to galling, where material welds to the tool. This ruins the surface finish and damages the tool.

This reactivity increases with temperature. As cutting speeds increase, so does the heat. This makes the chemical reaction more likely. Choosing the right tool material is essential.

3. Significant Work Hardening

Titanium hardens when it is worked. This means cutting it makes the surface harder. Each pass of the tool makes the next pass more difficult. This increases cutting forces and tool wear.

Work hardening can be a major issue. It requires sharp tools and a rigid setup. You must avoid dwelling or rubbing the tool on the surface.

4. Low Modulus of Elasticity

Titanium is less rigid than steel. This is its low modulus of elasticity. The material can deflect away from the cutting tool. This causes chatter and vibration.

This deflection can lead to an inaccurate cut. It also puts more stress on the tool. A rigid machine and sharp tools are needed. This helps to minimize this effect.

5. High Cutting Forces

Despite its elasticity, titanium requires high cutting forces. This is due to its high strength, especially in its alloys. These forces can cause tool deflection and vibration.

High forces also generate more heat. This adds to the thermal problems. Your machine setup must be very rigid. This is needed to withstand these high forces.

How to Overcome These Challenges?

You can overcome these challenges with the right approach. It involves careful planning and the right tools. Here are some key strategies.

Choose the Right Cutting Tools

Use tools made from carbide or ceramic. These materials can withstand high temperatures. Look for tools with sharp, positive rake angles. This helps to reduce cutting forces.

Coatings like Titanium Nitride (TiN) can help. They reduce friction and prevent galling. Always use the sharpest tools possible.

Optimize Speeds and Feeds

Slower cutting speeds are generally better. This helps to reduce heat buildup. A consistent feed rate is also important. This prevents work hardening from tool dwelling.

A "high feed, low speed" strategy often works well. This approach removes material efficiently. It also keeps temperatures under control.

Use High-Pressure Coolant

Coolant is essential for machining titanium. A high-pressure coolant system is highly effective. It helps to flush chips away from the cutting zone. It also cools the tool and workpiece effectively.

Directing the coolant precisely at the cutting edge is key. This prevents heat from building up. It also reduces the risk of chemical reactions.

Ensure Maximum Rigidity

A rigid machine setup is crucial. This includes the machine, tool holders, and workpiece clamping. Rigidity minimizes vibration and chatter. This leads to better accuracy and tool life.

Keep tool overhangs as short as possible. Use a robust workholding solution. This ensures the workpiece is held securely.

Which Titanium Grade is Best?

The most common titanium alloy is Ti-6Al-4V (Grade 5). It offers a great combination of strength and corrosion resistance. However, it is also one of the more difficult grades to machine.

For applications requiring easier machinability, commercially pure titanium (Grade 2) is a good option. It is less strong but easier to work with. The best grade depends on your specific application needs.

Applications of Machined Titanium

Because of its excellent properties, machined titanium is used in many industries.

- Aerospace: Aircraft frames, engine components, landing gear.

- Medical: Surgical implants, dental implants, medical devices.

- Automotive: High-performance engine parts, exhaust systems.

- Marine: Propeller shafts, and components exposed to saltwater.

Our Titanium CNC Machining Services

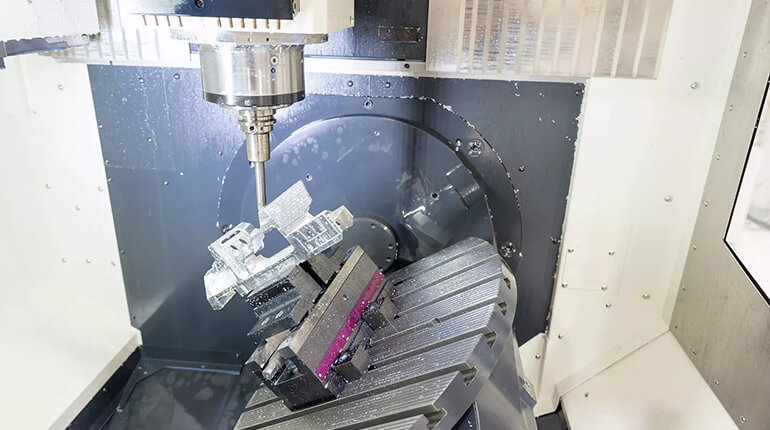

Machining titanium can be complex. It requires expertise and the right equipment. At Standard Machining, we specialize in CNC machining titanium. We understand the challenges and how to overcome them.

Our team has the experience to deliver high-quality titanium parts. We focus on precision, efficiency, and fast delivery. Contact us today to discuss your titanium machining needs.

Conclusion

Titanium is a valuable material. Its strength and light weight make it ideal for many uses. However, machining it is challenging. By understanding these challenges, you can find success. Use the right tools, speeds, and coolant. A rigid setup is also key.

FAQs about Machining Titanium

1. What is the biggest challenge in machining titanium?

The biggest challenge is managing heat. Titanium's poor thermal conductivity means heat builds up at the cutting edge. This leads to rapid tool wear and can damage the workpiece.

2. Can you use standard cutting tools for titanium?

It is not recommended. You should use tools specifically designed for titanium. These are typically made of carbide with special coatings. They have sharp edges to reduce cutting forces.

3. Why is coolant so important for machining titanium?

Coolant is critical for several reasons. It reduces heat, clears chips from the cutting area, and prevents the titanium from reacting with the tool. High-pressure coolant is most effective.

4. What is work hardening?

Work hardening is when a metal becomes harder after being plastically deformed. When machining titanium, the cutting action hardens the surface. This makes subsequent cuts more difficult and increases tool wear.

5. How can you prevent chatter when machining titanium?

To prevent chatter, ensure maximum rigidity in your setup. Use a robust machine, secure workholding, and short tool overhangs. Sharp cutting tools and optimized feeds and speeds also help to minimize vibrations.