Is Titanium Always Worth the Cost

Titanium is a metal known for its impressive strength and light weight. But its high price often raises the question: is titanium always worth the cost?

This article will explore titanium's unique properties and high costs. We will help you decide if it is the right material for your project by analyzing its value.

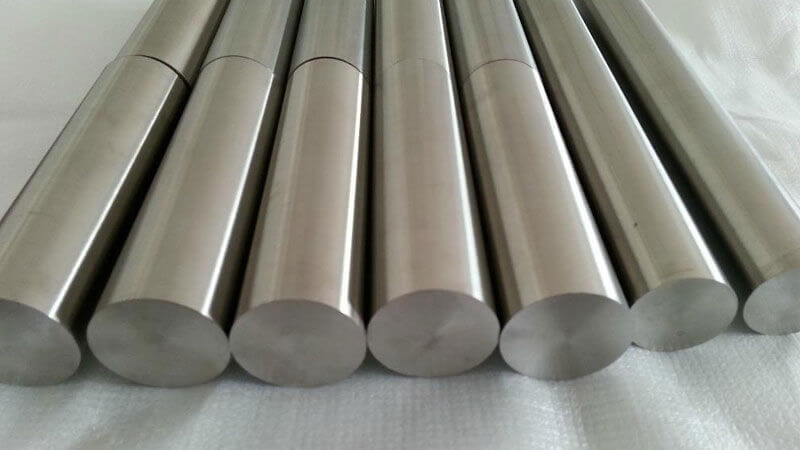

Understanding Titanium's Core Properties

Titanium has several key features. These make it highly valuable for specific applications. Understanding these properties is key to knowing its true worth.

High Strength-to-Weight Ratio

Titanium is incredibly strong. It is as strong as many steels. Yet, it is about 45% lighter. This makes it ideal for parts that need to be both strong and lightweight. This property is crucial in industries like aerospace.

Superior Corrosion Resistance

This metal has amazing resistance to rust and corrosion. It stands up to seawater, chlorine, and many industrial chemicals. This durability means titanium parts last longer. They require less maintenance than other metals.

Biocompatibility and Heat Resistance

Titanium is non-toxic to the human body. The body does not reject it. This makes it perfect for medical implants. It also maintains its strength at high temperatures. This is a vital property for jet engines and spacecraft.

Why is Titanium So Expensive?

Several factors contribute to titanium's high price tag. The journey from ore to finished product is complex and costly. This affects the final price you pay.

Raw Material Extraction Costs

Titanium is not rare in the Earth's crust. However, it is difficult to extract from its ore. The process is multi-staged and energy-intensive. This complex extraction process is a primary driver of its high initial cost.

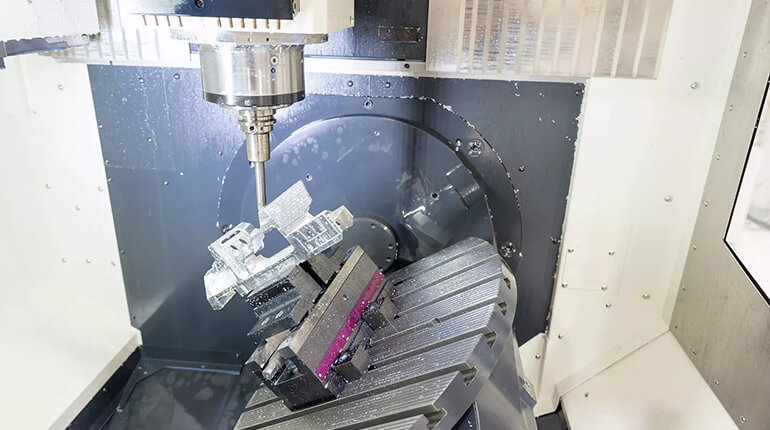

Difficulties in CNC Machining

Machining titanium is a challenge. It has low thermal conductivity. Heat does not dissipate quickly from the cutting tool. This causes rapid tool wear and requires slower machining speeds. Specialized tools and coolants are necessary. These factors increase machining time and costs.

Specialized Welding and Finishing

Welding titanium requires a special process. It must be done in an inert gas environment. This prevents it from reacting with oxygen. Finishing processes can also be more complex. They add to the overall manufacturing cost.

When Titanium is the Best Choice

In some fields, the benefits of titanium far outweigh its cost. Its unique properties are essential for performance and safety. There is often no suitable substitute.

Aerospace and Defense Applications

The aerospace industry relies heavily on titanium. It is used for engine components, airframe structures, and landing gear. Its strength and light weight improve fuel efficiency. Its heat resistance is vital for high-speed flight.

Medical Implants and Devices

Titanium is the top choice for medical implants. This includes hip and knee replacements and dental implants. Its biocompatibility and corrosion resistance are key. It ensures the implant is safe and lasts a long time inside the body.

Marine and Chemical Processing

In harsh environments, titanium excels. It is used in marine applications due to its resistance to saltwater corrosion. The chemical industry uses it for tanks and piping. It handles corrosive chemicals without degrading.

Titanium vs. Steel Cost Analysis

When choosing between titanium and steel, consider more than just the raw material price.

- Initial Cost: Titanium is significantly more expensive per pound than most common stainless steel alloys.

- Machining Cost: Machining titanium can be 2-3 times more expensive than machining steel due to slower speeds and increased tool wear.

- Lifecycle Cost: For long-term applications, titanium can be more cost-effective. Its corrosion resistance means fewer replacements and less maintenance over the product's life.

Titanium vs. Aluminum Performance

Aluminum is another lightweight metal, but its performance differs greatly from titanium.

- Strength: Titanium is about twice as strong as the most common aluminum alloys.

- Durability: Titanium offers superior resistance to fatigue and impact. It also performs much better at high temperatures where aluminum would soften.

- Cost: Aluminum is much cheaper and easier to machine than titanium, making it a good choice when high strength is not the primary requirement.

When to Choose Other Metals

Titanium is not always the answer. For many projects, other metals are a better fit.

Choose steel when strength is the top priority and weight is not a major concern. Its low cost makes it ideal for construction and many industrial applications.

Choose aluminum when you need a lightweight and affordable material. It is perfect for automotive parts, consumer electronics, and applications where high strength is not essential.

Calculating Your Project's True ROI

To understand if titanium is worth it, you must look at the big picture. Calculate the total cost of ownership. This includes material cost, manufacturing, maintenance, and the expected lifespan of the part.

A higher initial investment in titanium can lead to significant long-term savings. This is especially true for products that operate in demanding environments. The extended life and lower maintenance can provide a strong return on investment (ROI).

Expert Titanium Machining Services

Working with titanium requires specialized knowledge and equipment. Choosing the right manufacturing partner is crucial for your project's success. An experienced shop understands the unique challenges of machining titanium.

At Standard Machining, we have the expertise to deliver high-precision titanium components. Our advanced CNC machines and skilled team ensure your parts meet the strictest quality standards. We focus on efficiency to provide you with a competitive cost and reliable delivery.

Conclusion

Titanium's high cost is justified when its specific benefits are essential. For applications demanding high strength, low weight, and excellent corrosion resistance, it is often the only choice. Carefully weigh its properties against your project's needs to make a smart investment.

FAQs About Titanium Costs

1. What is the main reason for titanium's high cost?

The primary reason is the difficult and energy-intensive process of extracting the metal from its ore. The challenges in machining and welding it also add significantly to the final cost of the component.

2. Is titanium stronger than diamond?

No, titanium is not stronger than diamond. Diamond is the hardest known natural material. Titanium is a metal known for its high strength-to-weight ratio, but it is much less hard than a diamond.

3. Can titanium be used for everyday products?

Yes, but it is not common due to its cost. You can find titanium in high-end consumer goods like sporting equipment, eyeglass frames, and watches. In these products, its lightweight, strength, and durability are key selling points.

4. How much more expensive is titanium than steel?

The raw material cost of titanium can be 5 to 10 times more expensive than common stainless steel alloys, or even more. The final part cost difference will be greater after factoring in the more difficult and costly machining processes.

5. Does titanium rust or tarnish?

Titanium is highly resistant to rust and tarnish. It forms a thin, protective oxide layer on its surface when exposed to air. This layer is extremely stable and protects the metal from corrosion in most environments, including saltwater.