Top 5 Documents Every Aerospace Project Must Include

When aerospace documents are missing or unclear, projects can run into big problems. Delays happen and tests sometimes fail. Many teams face these challenges, but clear documents like DFMEA, PFMEA, and config files help a lot.

Teams find that these key files make work smoother.

In this blog, we'll explore how five important documents keep mission control running strong. From the Project Requirements Document to the Schedule and Budget Report, each file helps guide teams step by step.

These tools also support flight simulator development with clear simulation plans everyone can follow.

Read on to learn which documents every aerospace team should keep close for simple access and greater success.

Project Requirements Document (PRD)

The Project Requirements Document, or PRD, gives a clear view of our mission goals. It outlines technical details and limits that guide us throughout the project.

Overview of mission objectives

Mission objectives shape every aerospace project. We define what needs to fly, what it must achieve, and the environment variables it will face. These details go into the Project Requirements Document, or PRD.

For example, if we design a drone, our goal might be to keep it airborne for three hours, transmit live video over five miles, and work in temperatures from -10°C to 50°C. We note these facts, set each one as a testable target, and make sure they guide every step.

We always match our mission needs with technical limits. Hardware-in-the-loop (HIL) tests help us simulate real flight conditions before final builds. This lets us tweak sub-systems, tiling routes, or cloud-based data sharing early.

Our background in CNC machining means we care about every detail, from layout to exec commands for system checks. Clear mission objectives make it easy to debug, track progress, and report success or changes to the team.

Clear goals prevent costly errors and missed deadlines.

Technical specifications and constraints

Technical specifications keep every part of our aircraft project on track. We list exact dimensions, weight limits, material choices, and system requirements. For example, we use Airbus A320 technical data to set our baseline for cabin pressure and engine thrust.

These numbers guide our choices for parts like fasteners and actuators. We must include environmental variables, or env_var, such as temperature, humidity, and vibration, because these affect both performance and safety.

Constraints shape our work, too. Budget, timeline, and regulations set limits. The FAA and EASA require strict records on aircraft noise and emissions. Each simulation must pass all test parameters and return a zero exit code.

Using bash scripts, we automate our test routines and make sure logs flow to stdout and stderr as needed. No step gets skipped. Hotkeys help us switch between design apps like Chrome and visualization tools in macOS, boosting our workflow.

With clear specs and rules in place, we stay ready to tie systems together in the next planning stage.

Systems Engineering Management Plan (SEMP)

The Systems Engineering Management Plan (SEMP) is vital for our projects. It helps us coordinate different subsystems and manage risks effectively.

Integration of subsystems

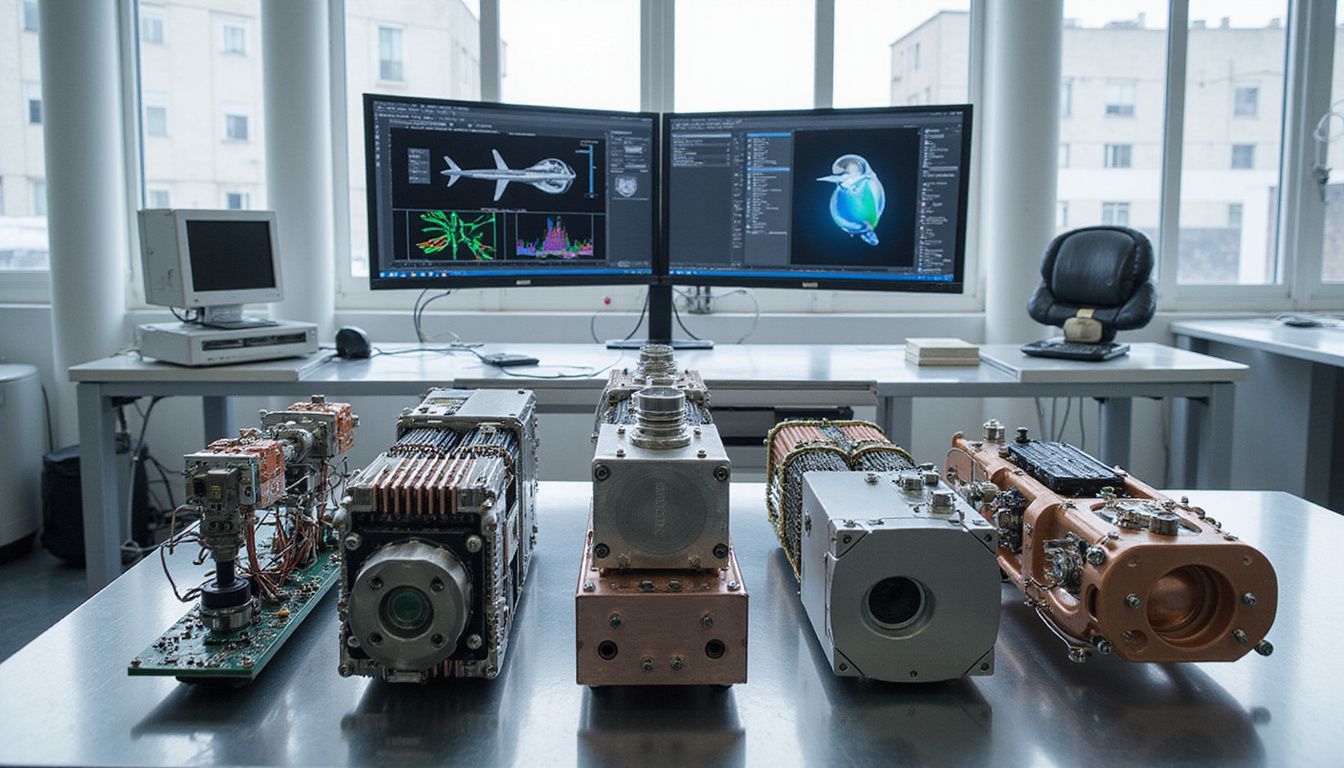

Subsystem integration links all our hardware and software units into one working system. We connect modules like avionics, propulsion, thermal control, and structure using clear interface documents.

Each module must meet technical specifications from the Project Requirements Document (PRD). We use simulating tools such as MATLAB Simulink or CATIA to check fit and function before assembly.

As mechanical design engineers, we know smooth integration prevents errors in later stages. For example, a simple mistake in the interface between flight controls and power systems can cause testing failures.

Using easy access icons in digital dashboards helps us switch quickly between subsystem views—kind of like using alt-tab on a computer with Colemak or Dvorak layouts for better workflow.

“Integration is not just about fitting parts together; it’s syncing their operations.”

Risk management strategies

We must identify and analyze risks early. This helps us avoid problems later. We can use tools like checklists and risk matrices to spot potential issues in our aerospace projects.

Each risk should have a clear plan, outlining how we will monitor it.

By prioritizing risks, we focus on the most serious ones first. Let’s involve our team in brainstorming solutions. Working together boosts creativity while strengthening our approach to risk management strategies.

Strong communication helps keep everyone aware of changes and updates during the project lifecycle.

Test and Evaluation Master Plan (TEMP)

The Test and Evaluation Master Plan, or TEMP, is key to any aerospace project. It lays out the methods we will use for testing our systems. We define how we will measure success too.

Clear criteria help us know if we are meeting our goals.

Testing methodologies

Testing is a crucial part of aerospace projects. It helps us ensure that our designs work as planned. We need clear methods to test every component and system.

- Simulation Testing: This method helps us predict how systems will behave in real-world conditions. We use computer models to simulate scenarios without the risk of physical failures.

- Prototype Testing: Building a prototype allows us to test our designs physically. It gives us a chance to see if everything fits and functions as expected in a working model.

- Environmental Testing: Aerospace components face tough conditions. We perform tests for temperature, pressure, and vibrations to check how these factors affect performance.

- Structural Testing: This involves applying forces to our components to see how they hold up under stress. We look for weaknesses that could lead to failure during flight.

- Flight Testing: This is the final step before certification. We fly full-scale aircraft or systems to observe their behavior in real flight conditions. Data from these tests shows if we meet safety regulations.

We use these methodologies throughout our projects, ensuring high quality and compliance with aerospace standards. Each testing phase helps us identify issues early on, saving time and resources later in the project lifecycle.

Evaluation criteria and success metrics

We need clear evaluation criteria and success metrics for our aerospace projects. These help us measure how well we meet our goals. We define specific benchmarks to compare results against.

For example, we can set targets for performance, safety, and reliability.

By using testing methodologies such as flight tests and simulations, we gather data on how our designs perform. This data helps us track whether we achieve project objectives or if adjustments are needed.

Success metrics guide us in understanding what works and what doesn't in the technical writing of our reports. They make sure that every step aligns with industry standards like those seen in e-learning modules for engineers.

Certification and Compliance Documentation

Certification and compliance documentation is key for any aerospace project. It ensures that we meet all safety standards and obtain necessary approvals from regulatory bodies.

Adherence to aerospace standards

Aerospace standards play a critical role in our projects. They ensure safety, quality, and performance in all designs. We need to follow these guidelines closely. This involves applying regulations set by groups like the FAA and NASA.

Our work must meet strict criteria.

Regulatory approvals are key to keeping our projects on track. They help us gain necessary certifications for aircraft or spacecraft. By adhering to aerospace standards, we confirm that every aspect of our design is reliable and safe for users.

This commitment builds trust with clients and stakeholders while ensuring project success.

Regulatory approvals and certifications

Regulatory approvals and certifications are crucial for our aerospace projects. They help ensure safety, quality, and compliance with industry standards. We must prove our designs meet the guidelines set by authorities like the Federal Aviation Administration (FAA) or the European Union Aviation Safety Agency (EASA).

These documents show that we follow all necessary rules and regulations. This process may involve multiple tests and evaluations to confirm that everything functions as intended. By obtaining these certifications, we demonstrate our commitment to excellence in design and engineering for our aerospace projects.

Project Schedule and Budget Report

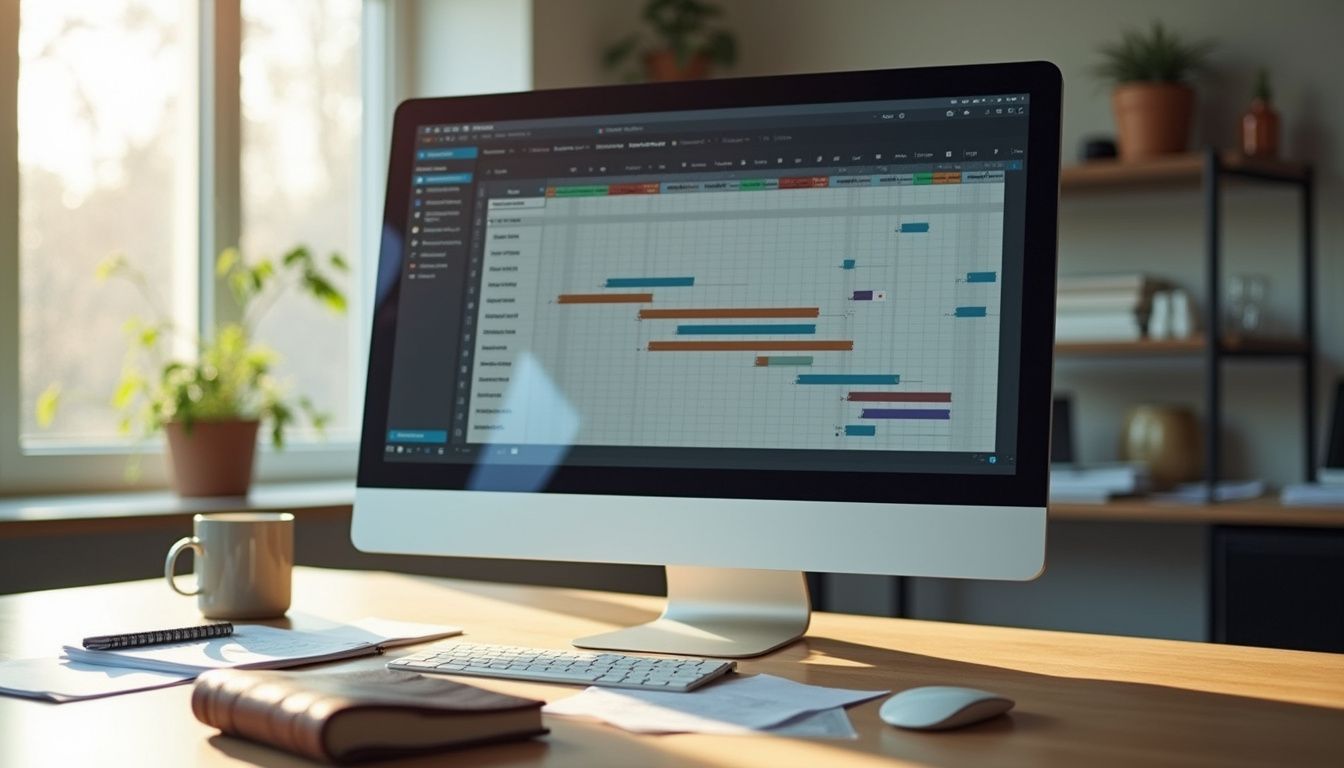

The Project Schedule and Budget Report shows our timeline for key tasks. It also details cost estimates and how we will use our resources efficiently.

Timeline of deliverables

We must keep track of our project timeline closely. A clear timeline helps us stay on schedule. Here are the key points for the timeline of deliverables:

- Project Kickoff: This marks the start of our project. We should hold a meeting to set expectations and assign roles.

- Phase Planning: Each phase needs its planning session. During this time, we will define tasks, set deadlines, and allocate resources.

- Milestone Dates: We will set specific dates for each milestone. These dates help us measure progress.

- Design Reviews: Regular design reviews are essential. We will schedule these meetings to assess work and gather feedback.

- Prototyping Stage: The prototyping phase comes after design reviews. We must build and test prototypes within this period.

- Testing Period: After prototyping, we enter testing phases. This is where we evaluate performance against our requirements.

- Final Deliverable Submission: The last step is submitting all final documents and products. This includes compliance reports and certifications.

- Review Sessions Post-Submission: Once everything is submitted, we need review sessions to discuss lessons learned and future improvements.

Staying focused on this timeline ensures smooth project flow in aerospace projects, supporting effective communication among our team members while adhering to aerospace standards as part of our strategy.

Cost estimation and resource allocation

Estimating costs and managing resources keep aerospace projects on track, on time, and within budget. We use proven tools and technical processes to ensure accuracy and transparency. The table below highlights core elements for mechanical design engineers.

| Aspect | Description | Tools/Methods | Key Points | Example |

|---|---|---|---|---|

| Cost Estimation | Calculate expected expenses across all project phases for labor, materials, and testing. | Parametric models, bottoms-up analysis, cost breakdown structure (CBS) |

| $10M for composite wing fabrication, based on similar past projects |

| Resource Allocation | Assign skilled personnel, machines, and budget to tasks and timelines. | Resource leveling in MS Project, Gantt charts, ERP systems |

| Assign 5 CAD engineers for 3 months to structural layout phase |

| Tracking & Reporting | Monitor progress and adjust resource use and funds allocation as needed. | Earned Value Management (EVM), dashboards, KPI trackers |

| Monthly report shows hardware spend is 8% under budget |

| Supplier & Material Costs | Integrate supplier quotes and raw material price trends into estimates. | Supplier databases, cost roll-up spreadsheets, historical data |

| Titanium price increase adds $250k to engine mount estimate |

| Contingency Management | Set aside budget and resources for risks and unplanned events. | Monte Carlo simulations, risk registers |

| Reserve $500k for late-stage design changes or supply delays |

Tracking schedules and aligning budgets with milestones keeps the team focused. Now, let’s examine documents on certification and compliance.

Conclusion

We covered the top five documents every aerospace project needs. Each document plays a key role in making our projects successful. The Project Requirements Document helps us understand our goals and limits.

The Systems Engineering Management Plan keeps everything working together smoothly. By using these documents, we can manage risks and ensure compliance with standards as we move forward in our work.

Proper planning sets us up for success!