The Best 5 Visual Management Tools for Shop Floors

It is often tough to keep shop floor information clear and easy to follow. Many teams face these same struggles every day. Visual management has made a big difference by helping people share updates faster and make fewer mistakes.

This method started with the Toyota Production System back in the 1950s.

In this blog post, we’ll talk about what really works for tracking work, helping teams communicate, managing projects, and solving problems with five top visual management tools.

Take a look to see which of these visual tools could help boost productivity on your shop floor today.

Kanban Boards for Workflow Management

Kanban boards help us manage our tasks. They make workflows clear and simple, showing what needs to be done next.

Kanban boards help us manage our tasks. They make workflows clear and simple, showing what needs to be done next.

How Kanban improves shop floor efficiency

We use Kanban boards to spot problems fast, cut downtime, and boost efficiency on the shop floor. Each card gives a real-time look at project management, workflow tracking, and inventory.

We see bottlenecks right away and take quick action to fix them. Using visual tools like these keeps everyone alert to issues that slow us down.

Clear labeling and signage mean our team always knows what is next in the workflow. Standardization helps us follow the same process every time, so errors drop and performance goes up.

With Kanban boards, we base decisions on hard data from the floor, not guesses. This supports lean manufacturing, empowers teamwork, and drives continuous improvement for quality management and operational excellence.

Ideal use cases for Kanban boards

After exploring how Kanban boosts shop floor efficiency, let's look at the top situations where Kanban boards shine. Kanban boards work best in fast-paced manufacturing settings, like CNC milling, turning, EDM, and precision grinding.

We track every job lot, from prototyping to full production runs. In our CNC machine shop, we map out workflowtracking using Kanban cards and digital dashboards. This helps us monitor parts for aerospace and defense contracts or small-batch runs for robotics and medical devices.

Clear visualization of tasks allows us to spot bottlenecks and quickly shift resources.

In team-based assembly or inspection lines, Kanban boards keep everyone on the same page. They support both group and individual task tracking across processes. For instance, we align assembly teams around key performance indicators (KPIs) with easy-to-read graphics on our boards.

Kanban fits lean production and Six Sigma tools like Value Stream Mapping or root cause analysis. We use it in daily planning meetings and recall checks too. The system adapts well to changing priorities in electronics or automotive projects, letting us react fast without losing control over logistics or compliance steps.

Using Kanban has sharpened cooperation between engineers and operators on the shop floor every day.

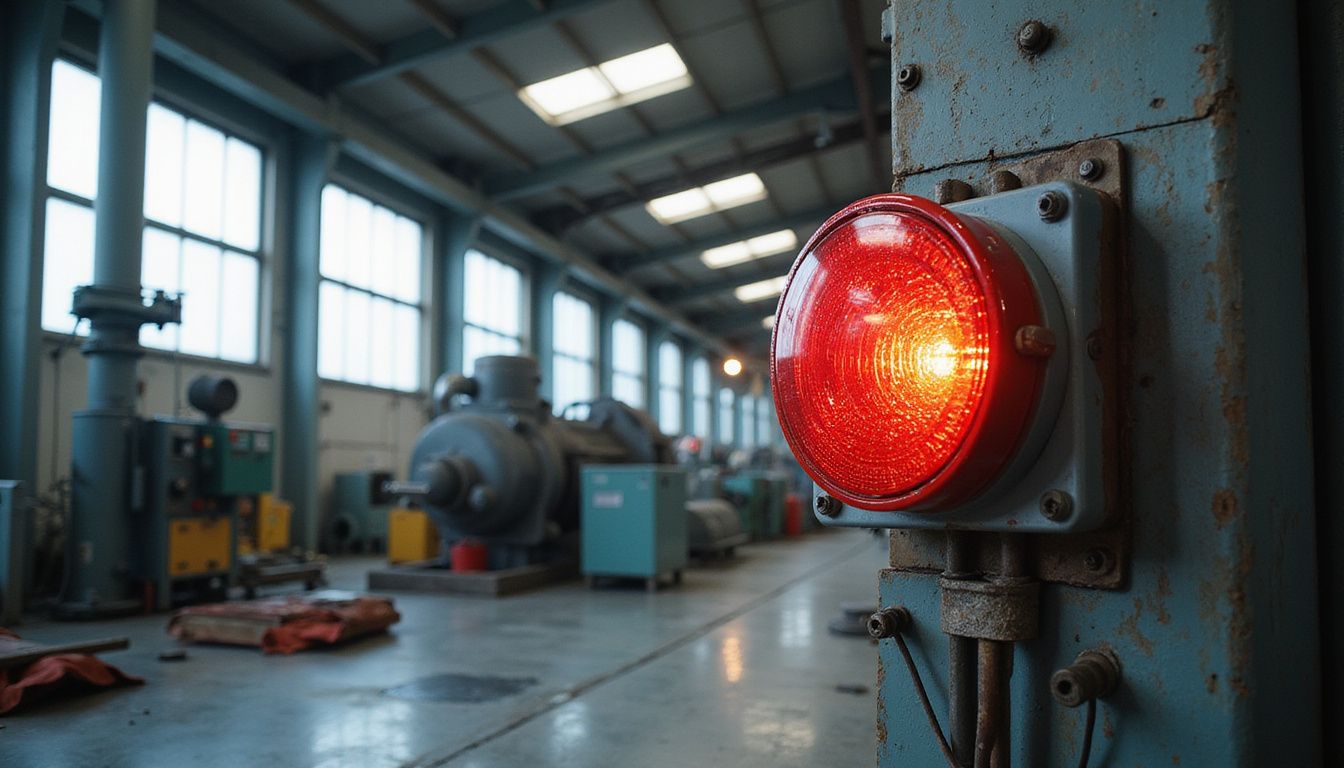

Andon Systems for Real-Time Problem Signaling

Andon systems provide real-time updates about problems on the shop floor. They assist us in identifying and resolving issues swiftly, enhancing our performance and safety in our operations.

Benefits of Andon in manufacturing environments

Real-time problem signaling systems, like Andon, help us spot issues right away on the shop floor. We see accurate, up-to-date data that boosts our decision-making. This fast feedback means we can solve problems quickly and avoid long delays.

With immediate alerts, our teams can stop production lines to address safety risks and prevent accidents.

We notice that Andon creates transparency and leads to better teamwork. It empowers every worker to call for help, which supports a culture of continuous improvement. Information is easy to share, which strengthens our business process and collaboration.

In high-mix, high-volume settings, Andon reduces downtime and supports Lean principles by cutting waste and keeping processes consistent.

With Andon, our teams feel empowered to solve problems fast and keep every process safe and smooth.

Examples of Andon system applications

Andon systems play a key role in manufacturing. They signal problems quickly and help teams respond effectively. Here are some examples of how we can apply Andon systems on the shop floor.

- In CNC machining centers, Andon lights indicate equipment breakdowns. This helps us know when a machine is down and needs attention.

- During assembly, Andon displays show quality control issues. When there’s a problem, we can fix it right away.

- Operators in automotive manufacturing use Andon cords to stop the production line. This allows us to address any detected issues immediately.

- In semiconductor and electronics industries, Andon systems escalate defects instantly. This quick action helps maintain product quality.

- Teams also use Andon for reporting safety incidents on the floor. It ensures that we respond promptly to any danger or risk.

- Combining Andon with digital dashboards gives us real-time updates on production status and historical trends; this enhances our decision-making capabilities.

These applications empower our team to solve intricate problems faster and improve efficiency in operations management.

Visual Management Boards

Visual management boards show key information clearly. They can include daily goals or help with 5S practices. These boards improve team talks and keep everyone informed. Using them builds a better workplace culture and boosts productivity.

Types of boards: daily management and 5S control boards

We utilize different types of boards to enhance our shop floor efficiency. Two important types are daily management boards and 5S control boards.

- Daily management boards track regular operational KPIs. They help us monitor production goals in real-time. These boards keep everyone informed about performance levels. We can visualize progress and make quick decisions based on the data.

- 5S control boards focus on organization, cleanliness, and safety standards. They remind us of the importance of maintaining a clean workspace. These boards display essential practices like sorting, straightening, shining, standardizing, and sustaining. Safety metrics are also shown here to ensure compliance with regulations.

These tools support lean management strategies by promoting teamwork and clear communication on the shop floor. Next, we will explore Andon systems for real-time problem signaling.

How these boards enhance team communication

Visual management boards enhance team communication in clear ways. They make information visible to all, which helps everyone stay informed. With real-time data displayed, we can see our goals and progress at a glance.

This transparency aligns us with common objectives.

These boards also encourage engagement and accountability among team members. We all notice how our work impacts the overall process daily. By having visual cues, comprehension improves, making it easier for us to understand tasks and expectations.

Such tools enhance hands-on learning too; they centralize information so that updates take less time and miscommunication is reduced.

Next, we will explore Value Stream Mapping for optimizing processes on the shop floor.

Value Stream Mapping (VSM) for Process Optimization

Value Stream Mapping helps us see how work flows in our processes. We can spot delays and waste, which lets us make faster improvements.

Identifying bottlenecks with VSM

VSM helps us spot bottlenecks in our processes. We see each step clearly, which allows us to track performance in real time. By mapping out the process, we find areas where work slows down or gets stuck.

This way, we can highlight waste and non-value-adding activities quickly.

When we notice a bottleneck, it becomes easy to prioritize actions for improvement. Visual tools make problems visible at every stage of production. We can use this information to make better decisions for optimizing our workflow.

VSM promotes teamwork by providing a shared reference that keeps everyone aligned with goals and tasks on the shop floor.

Steps for implementing VSM on the shop floor

To implement Value Stream Mapping (VSM) on the shop floor, we need to take clear steps. Each step helps us improve our processes and identify problems.

- Start by assessing each stage of the current process. Gather data about how things work now. This will give us a good foundation.

- Involve all team members and stakeholders early in the process. Their input is valuable for accurate mapping and leads to better buy-in.

- Train staff on VSM principles and practices. This will enhance their understanding, making them more effective in using the tools.

- Choose suitable visual tools for mapping workflows and data. Tools like flowcharts, decision trees, or digital dashboards can be very helpful.

- Roll out VSM initiatives gradually, starting with pilot areas first. Testing in smaller sections allows us to make adjustments before a full launch.

- Monitor progress regularly and update our maps as needed. Keeping these maps current helps reflect changes in real-time.

- Standardize mapping procedures across all teams and shifts for consistency. This reduces confusion and makes it easier to share information.

- Use findings from VSM to drive continuous improvement efforts within our lean production system. These insights will guide future changes.

Following these steps sets us up for success in optimizing our shop floor processes through VSM while promoting creativity and problem-solving within our teams.

Digital Dashboards for Performance Metrics

Digital dashboards provide immediate updates on performance metrics. They assist teams in monitoring key performance indicators (KPIs) effectively. We can utilize tools like Tableau and Microsoft Power BI to create these valuable dashboards in the manufacturing space. This allows managers to make prompt decisions based on live data, enhancing our efficiency.

Real-time updates and KPI tracking

![]()

Real-time updates keep us informed about critical KPIs on the shop floor. These dashboards show current data, allowing for smart decision-making. With automated data feeds, we always see an accurate picture of operations.

This helps us spot trends quickly and respond to issues as they arise.

Tracking KPIs supports our goal of continuous improvement. We measure production rates, quality metrics, and downtime effectively. Teams stay engaged when they can see performance at a glance.

Accountability increases as everyone knows their role in meeting targets. Real-time visualization boosts our productivity while strengthening corporate culture on the shop floor.

Popular tools for digital dashboards in manufacturing

We can enhance our shop floor performance with digital dashboards. These tools help us track key metrics and improve efficiency.

- Utrakk Dashboards offer real-time updates. They consolidate data for easy access. We can see production status and maintenance information at a glance.

- Virtual whiteboards support remote collaboration. Team members share ideas and plan together. This tool allows us to brainstorm effectively, no matter where we are.

- KPI tracking software helps us measure our progress. It captures data on important performance indicators, making it simple to analyze trends.

- Lean and Six Sigma tools fit well with digital dashboards. These methodologies improve processes and reduce waste, boosting our productivity.

- Custom dashboards provide insights for different roles in manufacturing. We can create reports that meet the specific needs of our teams, fostering empowerment across departments.

- Data analytics platforms turn intricate data into clear visuals. They help us make informed decisions based on statistical analysis.

- Standardization is key for effective communication across multiple sites. Digital dashboards help us achieve this by centralizing information and ensuring everyone stays informed.

Using these tools enhances our ability to manage workflows efficiently while keeping everyone connected and informed on the shop floor.

Conclusion

Choosing the right visual management tools can transform our shop floor. Kanban boards streamline tasks, while Andon systems signal problems quickly. Visual management boards keep us informed every day.

Value Stream Mapping helps us spot slow points in our process. Digital dashboards update us on performance instantly, making it easy to track key metrics. Together, these tools enhance communication and teamwork, leading to better results for all of us.