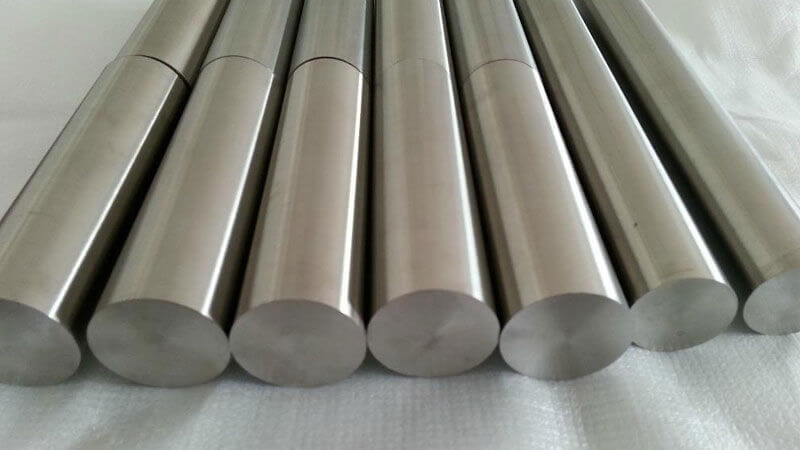

Common Applications for Commercially Pure Titanium

Commercially Pure (CP) Titanium offers exceptional corrosion resistance and ductility for various critical industries. Understanding its specific applications helps you select the right material for your precision manufacturing projects.

This guide covers the four primary grades of CP Titanium, their specific properties, and industrial uses. You will also learn about machining challenges and how to choose the best grade for your needs.

What is Commercially Pure Titanium and Its Grades?

You often hear about titanium alloys, but unalloyed titanium plays a massive role in manufacturing. It is defined by its chemical purity rather than added alloying elements.

Understanding the ASTM Grading System

The ASTM grading system categorizes unalloyed titanium into four distinct grades: Grade 1, 2, 3, and 4. These grades differ primarily based on their yield strength and allowable oxygen levels. As the grade number increases, the yield strength and oxygen content typically increase.

The Composition of Unalloyed Titanium

CP Titanium consists of 99% or more titanium. The remaining small percentage includes trace elements like iron, oxygen, carbon, and nitrogen. Even these microscopic variations significantly alter the mechanical behavior of the metal.

Key Properties of Commercially Pure Titanium

Before selecting a material, you must understand why engineers prefer CP Titanium over steel or aluminum.

Superior Corrosion Resistance

This is the primary selling point of unalloyed titanium. It naturally forms a stable, continuous oxide film on its surface. This film protects the component from aggressive environments, including saltwater and acidic solutions.

High Ductility and Formability

Unlike harder titanium alloys, CP grades exhibit excellent ductility. You can easily form, bend, and weld these materials. This makes them ideal for complex geometries that do not require extreme tensile strength.

Biocompatibility and Non-Magnetic Nature

Titanium is biologically inert. Your body does not reject it, making it perfect for medical use. Additionally, it is non-magnetic, which is crucial for interference-sensitive electronic and medical equipment.

Common Applications for Commercially Pure Titanium by Industry

You will find unalloyed titanium in sectors where failure is not an option.

Medical and Dental Implants

CP Titanium is the standard for dental implants and bone plates. Its ability to osseointegrate (fuse with bone) is unmatched. Grade 4 is often used here due to its higher strength.

Chemical Processing and Heat Exchangers

Factories handling chlorine, acids, or sulfates rely on CP Titanium. It resists crevice corrosion better than stainless steel. You will see it in tanks, valves, and extensive piping systems.

Marine and Desalination Components

Saltwater rapidly destroys most metals, but not titanium. Desalination plants use miles of Grade 2 titanium tubing. It ensures longevity and reduces maintenance costs in marine environments.

Architectural Structures and Consumer Goods

Architects use titanium sheets for roofing and cladding due to their aesthetic appeal and durability. You also encounter it in consumer goods like eyeglass frames and watch cases.

Choosing the Right CP Titanium Grade (1-4)

Selecting the correct grade depends on balancing strength against formability.

Grade 1: Softest with Maximum Formability

Grade 1 has the lowest oxygen content and strength. You should choose this for parts requiring deep drawing or severe forming. It possesses excellent impact toughness.

Grade 2: The "Workhorse" for Industrial Use

This is the most widely used titanium grade globally. It offers a balanced combination of moderate strength and reasonable ductility. If you need a general-purpose solution, start here.

Grade 3: Moderate Strength Applications

Grade 3 is less common but valuable. It provides higher strength than Grade 2 but sacrifices some formability. It is often used in pressure vessels requiring higher mechanical ratings.

Grade 4: Highest Strength Among Pure Grades

If you need high strength without using an alloy, choose Grade 4. It has the highest oxygen and iron content. It is extensively used in medical hardware.

Commercially Pure Titanium vs. Titanium Alloys

You might wonder if you should just use Ti-6Al-4V (Grade 5) instead.

Strength and Hardness Comparison

Titanium alloys are significantly stronger than CP grades. Grade 5 has a tensile strength nearly double that of Grade 2. However, CP grades offer superior corrosion resistance.

Cost and Machinability Differences

CP Titanium is generally more affordable than complex alloys. However, it is "gummy" during machining. Alloys tend to chip break better, while CP titanium produces long, stringy chips.

Challenges in CNC Machining Commercially Pure Titanium

Machining CP Titanium requires specific strategies to ensure precision and surface finish.

Managing Heat Generation and Tool Wear

Titanium has poor thermal conductivity. Heat concentrates at the cutting edge rather than dissipating into the chip. You must use high-pressure coolant to prevent rapid tool failure.

Preventing Galling and Work Hardening

CP Titanium tends to stick to the cutting tool, causing galling. It also work-hardens instantly if the tool rubs. You need to maintain constant feed rates and use sharp, positive-rake tools.

Standard Machining’s Expertise in Titanium Parts

At Standard Machining, we specialize in overcoming the unique challenges of titanium manufacturing. Our facility utilizes advanced 3, 4, and 5-axis CNC machines optimized for difficult materials. We understand how to manage heat and chip evacuation to hold tight tolerances on Grade 2 and Grade 4 components.

Conclusion

CP Titanium excels in corrosion resistance and formability across medical and industrial fields. Choosing the right grade ensures optimal performance for your specific engineering requirements.

Contact Standard Machining today for a quote on your precision Titanium manufacturing needs.

FAQs

Is Commercially Pure Titanium magnetic?

No, CP Titanium is non-magnetic. This property makes it safe for MRI machines and ideal for sensitive electronic housing.

What is the difference between Grade 2 and Grade 5 Titanium?

Grade 2 is commercially pure and highly corrosion-resistant. Grade 5 is an alloy (Ti-6Al-4V) known for high strength but lower formability.

Does CP Titanium rust?

No, it does not rust like steel. It forms a protective oxide layer that prevents oxidation, even in saltwater environments.

Is CP Titanium hard to machine?

Yes, it can be challenging due to its "gummy" nature and heat retention. However, experienced machinists use specific tooling strategies to achieve