Why Engineers Choose Aluminum 6061 for CNC Parts

I’ve quoted thousands of CNC projects in the last decade. When the drawing lands on my desk with no alloy callout, 9 times out of 10 the engineer ends up choosing aluminum 6061-T6. Here’s exactly why — and when you should (or shouldn’t) follow the crowd.

This guide breaks down the real-world performance, data-backed numbers, and hidden gotchas of the world’s most popular CNC aluminum.

What Is Aluminum 6061-T6 Alloy?

Understanding the Chemical Composition

6061 contains:

- 95.8–98.6% Aluminum

- 0.8–1.2% Magnesium

- 0.4–0.8% Silicon

- 0.15–0.40% Copper

Magnesium + silicon form Mg₂Si precipitates during heat treatment — that’s where the strength comes from.

What Does the “T6” Temper Mean?

Solution heat-treated at 990 °F, water quenched, then artificially aged at 350 °F for 8–18 hours. T6 delivers the best balance of strength and ductility. T4 (naturally aged) is softer and rarely used for machined parts.

5 Key Reasons Engineers Prefer Aluminum 6061

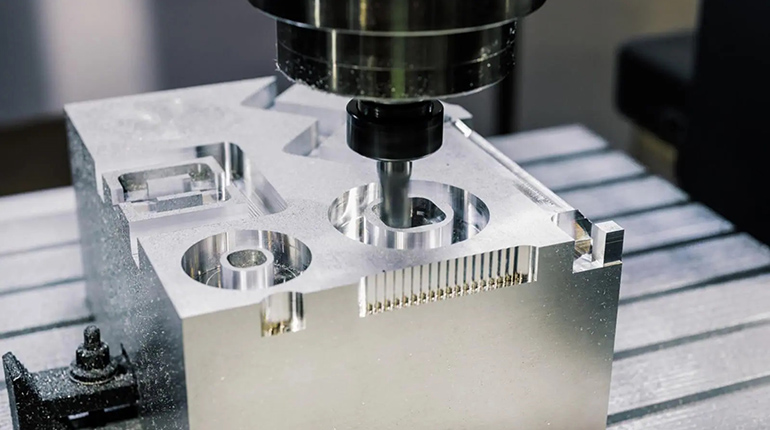

Excellent Machinability and Production Speed

6061 chips break beautifully, gives mirror finishes at 800–1200 SFM, and rarely builds up on tools. Cycle times are typically 30–50% faster than 7075 or stainless.

Superior Strength-to-Weight Ratio

Density: 2.70 g/cm³ (1/3 of steel)

Yield strength: 40 ksi (276 MPa)

That’s strong enough for structural frames, yet light enough for drones and robotics.

High Corrosion Resistance for Harsh Environments

Forms a natural oxide layer. With clear anodize or chem-film, it survives CASS and salt-spray tests far longer than 7075.

Good Weldability and Formability

Accepts TIG/MIG without cracking when using 4043 or 5356 filler. Post-weld heat treatment can restore full T6 strength.

Cost-Effectiveness for Prototyping and Production

Bar stock is ~20–30% cheaper than 7075 and always in stock. No premium for small quantities.

Mechanical Properties of Aluminum 6061

| Property | 6061-T6 Value | Units |

| Ultimate Tensile Strength | 45 ksi (310 MPa) | |

| Yield Strength | 40 ksi (276 MPa) | |

| Elongation | 12–17% | |

| Brinell Hardness | 95 | HB |

| Thermal Conductivity | 167 W/m·K |

Hardness and Thermal Conductivity

95 HB is soft enough for easy tapping but hard enough to resist galling in sliding applications. 167 W/m·K makes it ideal for heat sinks and electronic chassis.

Aluminum 6061 vs. 7075: Which Should You Should Choose?

| Factor | 6061-T6 | 7075-T6 | Winner |

| Yield Strength | 40 ksi | 73 ksi | 7075 |

| Machinability | Excellent | Fair | 6061 |

| Corrosion Resistance | Very Good | Poor (needs coating) | 6061 |

| Price per lb | $3.80–$4.50 | $6.50–$8.00 | 6061 |

| Weldability | Yes | Almost never | 6061 |

When to Stick with 6061

- Prototypes & production < 10,000 pcs

- Any welded assemblies

- Outdoor or chemical exposure

- Tight deadlines and budgets

When to Upgrade to 7075

- Aerospace structural fittings needing > 60 ksi yield

- High-stress racing or defense parts

- You can justify the extra cost and longer lead times

Best Surface Finishes for Aluminum 6061 Parts

Anodizing (Type II and Type III)

Type II (Mil-A-8625): decorative + 8–12 µm corrosion protection

Type III hardcoat: 25–50 µm thick, 60–70 Rockwell C hardness

Powder Coating and Bead Blasting

Powder gives thick, durable color. Bead blast + clear anodize is my favorite for premium cosmetic parts.

Chem Film (Chromate Conversion)

Mil-DTL-5541 Class 1A or 3: thin, conductive, perfect for electrical grounding and paint prep.

Common Industrial Applications for Aluminum 6061

Automotive and Aerospace Components

Suspension brackets, gearbox housings, satellite brackets.

Consumer Electronics and Enclosures

MacBook frames, GoPro housings, rack-mount servers.

Medical Devices and Optical Fixtures

MRI-compatible bases, laser alignment plates, surgical instrument trays.

Standard Machining’s Custom Aluminum CNC Services

We keep 6061-T6 plate and round bar in every thickness from 0.125" to 12" on the shelf. 3-, 4-, and 5-axis machines run 24/7 with ±0.0005" tolerances and full first-article inspection reports. Most quotes returned same day, prototypes in 3–7 days.

Conclusion

Aluminum 6061-T6 remains the default choice for 80%+ of machined parts because it’s strong, light, machinable, weldable, corrosion-resistant, and affordable. Only upgrade to 7075 when you truly need the extra strength.

Send your 6061 part drawing to rfq@standardmachining.com — I’ll review it personally and get you a quote before close of business today.

FAQs about Aluminum 6061

Is Aluminum 6061 magnetic?

No. It is completely non-magnetic (permeability ≈ 1.00002).

Can Aluminum 6061 be welded easily?

Yes — TIG or MIG with 4043/5356 filler. Pre-heat not required.

How does 6061 compare to 6063 aluminum?

6063 is softer, extrudes better, and has superior surface finish → architectural shapes. 6061 is stronger and far better for machining structural parts.

Is Aluminum 6061 suitable for marine applications?

Yes, especially with Type III anodize or marine-grade powder coat. Many boat fittings and underwater drone housings are 6061.

Need 6061 parts fast and perfect? Drop your file now — I’m waiting.