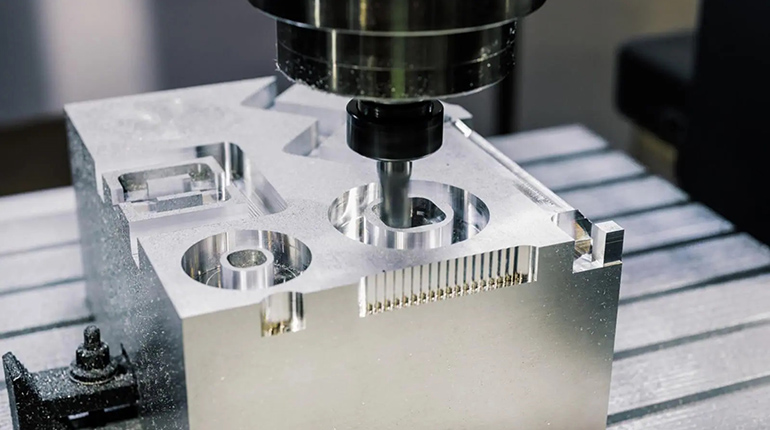

Solving Common Kovar Machining Challenges

Kovar machining presents unique manufacturing challenges due to the alloy’s specific thermal and mechanical properties. This guide explores solving common Kovar machining challenges effectively.

You will learn about Kovar's properties, why it is difficult to cut, and seven pro tips for success. Master this alloy today.

What is Kovar and Why Use It?

Kovar is a nickel-cobalt-iron alloy famous for its unique expansion characteristics. You typically use it in electronics where metal must seal to glass or ceramic.

Key Properties of Kovar Alloy

Kovar consists of roughly 29% nickel, 17% cobalt, and the balance iron. It offers high tensile strength and excellent thermal stability.

It is ferromagnetic and maintains its properties across a wide temperature range. This makes it indispensable for high-reliability applications.

The Importance of Thermal Expansion Matching

The primary reason you choose Kovar is its Coefficient of Thermal Expansion (CTE).

Its expansion rate nearly matches hard borosilicate glass and alumina ceramics. This matching prevents seals from cracking as temperatures change.

Why is Machining Kovar So Difficult?

Many machinists compare Kovar to Stainless Steel 316, but it is often more difficult. It requires patience and specific strategies.

The Challenge of Work Hardening

Kovar is notorious for rapid work hardening.

If your tool rubs instead of cuts, the material surface hardens instantly. This creates a hard shell that damages your cutting edges.

Dealing with Gummy Material Texture

The alloy is "gummy" and soft in its annealed state.

It does not chip away cleanly. Instead, the material tends to plow and drag. This leads to a Built-Up Edge (BUE) on your tool.

7 Pro Tips for Machining Kovar Alloy Effectively

To achieve precision, you must adapt your workflow. Here are seven strategies to master this tough alloy.

Selecting the Right Cutting Tools

You should use sharp, carbide tools. High-speed steel (HSS) wears out too quickly against the abrasive cobalt content.

Choose tools with wear-resistant coatings like TiCN. These coatings extend tool life significantly during long production runs.

Optimizing Feeds and Speeds

Speed control is critical for Kovar.

You must run at lower speeds, similar to machining tough stainless steel. However, you need a heavy feed rate to prevent rubbing.

Effective Coolant Strategies

Heat generation causes work hardening. You must control the temperature.

Use a high-volume flood coolant. This washes away chips and keeps the cutting zone cool. Avoid cutting dry at all costs.

Maintaining Rigid Setups

Vibration is the enemy of Kovar machining.

Ensure your workpiece is clamped securely. Use shorter tool holders to minimize deflection. Rigidity prevents the chatter that ruins surface finishes.

Utilize Climb Milling

Always use climb milling rather than conventional milling.

Climb milling directs heat into the chip, not the workpiece. This reduces the chance of work hardening the material surface.

Watch Your Depth of Cut

Your depth of cut should always exceed the work-hardened layer from the previous pass.

If you take a cut that is too shallow, you will simply burnish the material. This destroys your cutter instantly.

Chip Control is Key

Because the material is gummy, chips can be long and stringy.

Use chip breakers to snap these strings. This prevents them from wrapping around your spindle or scoring the part.

Kovar vs. Invar: Understanding the Key Differences

People often confuse these two low-expansion alloys, but they serve different purposes.

Invar (36% Nickel) has a CTE near zero. You use it where dimensional stability is paramount, like precision instruments.

Kovar has a higher CTE. It is specifically engineered to match the expansion curve of sealing glasses.

Common Applications of Kovar in High-Tech Industries

You will find this alloy in industries where failure is not an option.

Aerospace and Defense Components

Satellites and microwave tubes use Kovar.

It ensures that hermetic seals remain intact in the vacuum of space. It withstands extreme thermal cycling during launch and orbit.

Electronics and Vacuum Tube Applications

This is the standard material for power tubes, X-ray tubes, and light bulbs.

It acts as the critical bridge between the glass envelope and the conductive metal leads.

Trust Standard Machining for Precision Kovar Services

Machining Kovar requires more than just good equipment; it requires experience.

At Standard Machining, we understand the nuances of this gummy, abrasive alloy. We utilize advanced CNC strategies to deliver tight tolerances and superior surface finishes.

Conclusion

Kovar is essential for hermetic sealing but notoriously difficult to machine due to work hardening. By using rigid setups, sharp carbide tools, and correct speeds, you can achieve precision results.

Do you need high-quality Kovar components delivered on time? Contact Standard Machining today for a quote on your next project.

FAQs: Kovar Machining

What is the best coolant for Kovar?

Water-based soluble oils are generally best. They provide the necessary cooling to prevent hardening and the lubricity to reduce friction.

Can Kovar be welded after machining?

Yes, Kovar has excellent weldability. It is frequently joined using TIG or laser welding in assembly processes.

What cutting speed is recommended for Kovar?

Start with surface speeds similar to Stainless 316. Usually, 150-200 SFM (Surface Feet per Minute) with carbide tools is a safe starting point.

Is Kovar magnetic?

Yes, Kovar is ferromagnetic at all temperatures up to its Curie point. You must account for this in magnetic applications.