A Guide to Medical Grade Titanium

Medical grade titanium is a top choice for implants and surgical tools. This guide covers everything you need to know about this remarkable material, helping you make informed decisions for your medical device manufacturing needs.

We explore its unique properties and common grades. You will also learn about its top applications, machining challenges, and how it compares to traditional materials like stainless steel for medical applications.

What is Medical Grade Titanium?

Medical grade titanium refers to specific titanium alloys designed for biomedical use. These materials must meet stringent standards set by organizations like ASTM and ISO to ensure they are safe for use within the human body.

To qualify, the material must be non-toxic and highly biocompatible. It also needs exceptional strength and durability. These properties ensure that implants and instruments perform reliably for years without causing adverse reactions.

Why is Titanium Used in Medicine?

Titanium's popularity in the medical field stems from four key properties. These characteristics make it uniquely suited for demanding applications, from dental implants to complex joint replacements. Understanding these benefits helps clarify why it is often the superior choice.

Superior Biocompatibility

Biocompatibility is a material's ability to exist in harmony with living tissue. Titanium is highly biocompatible because your body does not see it as a foreign object. It forms a stable oxide layer that prevents it from reacting with bodily fluids, ensuring patient safety.

High Strength-to-Weight Ratio

Titanium is as strong as steel but approximately 45% lighter. This high strength-to-weight ratio is a significant advantage. For patients, it means implants are durable yet lightweight. For surgeons, it results in instruments that are easier to handle, reducing fatigue.

Excellent Corrosion Resistance

The human body is a challenging environment. Titanium excels here due to its outstanding corrosion resistance. The passive oxide film on its surface protects it from attack by bodily fluids. This prevents the release of harmful ions and ensures the implant's long-term structural integrity.

Osseointegration Properties

Osseointegration is a unique phenomenon where bone grows directly onto the titanium surface. This process creates a permanent, stable bond between the implant and the patient's bone. It is the primary reason for the high success rate of titanium dental and orthopedic implants.

Common Medical Titanium Grades

Not all titanium is the same. Different applications call for different grades, each with a unique composition and set of mechanical properties. Choosing the correct grade is critical for the success and safety of a medical device.

Grade 5 Titanium (Ti-6Al-4V)

Often called the "workhorse" of medical alloys, Grade 5 is the most widely used titanium. It is an alloy of titanium with 6% aluminum and 4% vanadium. This composition offers an excellent combination of strength, light weight, and corrosion resistance for medical components.

You will find it in orthopedic implants like hip and knee joints. It is also common in trauma plates and bone screws where high strength is essential.

Grade 23 Titanium (Ti-6Al-4V ELI)

Grade 23 is a higher-purity version of Grade 5. The "ELI" stands for "Extra Low Interstitials," meaning it has less oxygen, nitrogen, and carbon. This enhanced purity improves its ductility and fracture toughness.

These properties make Grade 23 ideal for applications requiring superior damage tolerance. Common uses include dental root implants, complex bone screws, and surgical staples.

Commercially Pure (CP) Titanium

Commercially Pure (CP) titanium is unalloyed and valued for its excellent corrosion resistance and formability. It comes in several grades, with Grade 2 and Grade 4 being common in medicine. While not as strong as its alloyed counterparts, it is perfect for specific applications.

CP titanium is often used to make pacemaker cases. It is also used for ventilator components and other devices where extreme strength is not the primary requirement.

Medical Titanium vs. Stainless Steel

For years, stainless steel (like 316LVM) was a standard for medical devices. However, titanium often proves to be a superior alternative for long-term implants.

| Feature | Medical Grade Titanium | Medical Stainless Steel |

| Biocompatibility | Excellent; inert in the body. | Good, but can release nickel ions. |

| Strength-to-Weight | Very high. | Moderate. |

| MRI/CT Scans | Non-magnetic; produces no artifacts. | Can be magnetic; may interfere with scans. |

| Corrosion Resistance | Superior; ideal for permanent implants. | Good, but less resistant than titanium. |

| Cost | Higher. | Lower. |

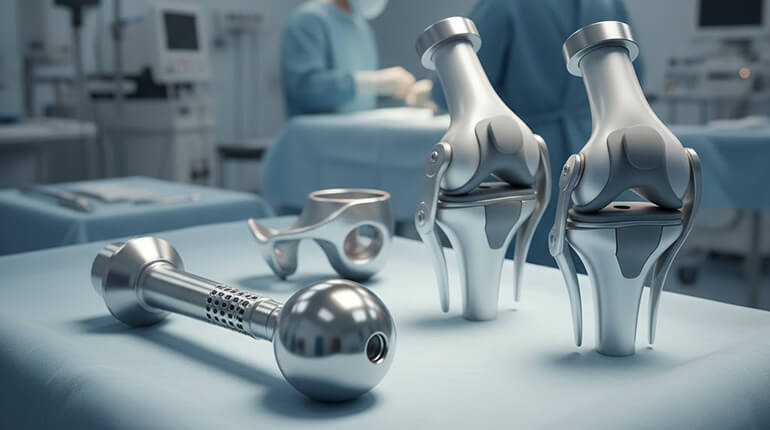

Top 5 Medical Applications

Titanium's unique properties make it the material of choice across many medical fields. Here are five of the most common applications where it plays a life-changing role.

Orthopedic Implants

Titanium is used to manufacture joint replacements for hips, knees, and shoulders. Its strength supports the body's weight, while its low weight reduces stress on surrounding bone. Osseointegration ensures these implants become a stable part of the skeleton.

Dental Implants

Titanium dental implants have revolutionized dentistry. These screw-like posts are placed in the jawbone, where they fuse with the bone through osseointegration. This provides a strong foundation for a replacement tooth with a success rate often exceeding 95%.

Surgical Instruments

Surgeons rely on instruments that are strong, lightweight, and durable. Titanium forceps, retractors, and scissors meet these needs perfectly. They reduce fatigue during long procedures and withstand repeated sterilization cycles without corroding.

Cardiovascular Devices

For devices that contact blood, biocompatibility is critical. Titanium is used for heart valve components, stents, and defibrillator parts. Its non-reactive nature ensures it will not cause blood clots or other adverse reactions inside the body.

Pacemaker Cases

A pacemaker's sensitive electronics must be protected within a durable, hermetically sealed case. CP titanium is the perfect material. It is strong, biocompatible, and can be easily formed into the required shape, keeping the device safe and functional for years.

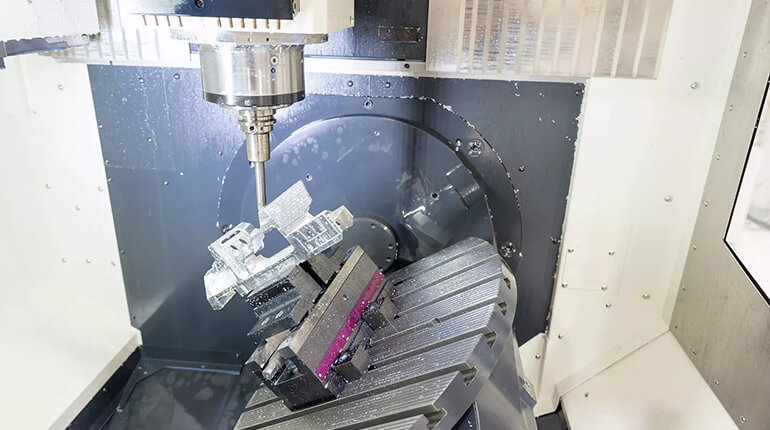

How to Machine Medical Titanium

Machining medical titanium presents unique challenges. Its properties require specialized knowledge and equipment to achieve the precise tolerances demanded by the medical industry.

The material's poor thermal conductivity causes heat to build up at the cutting tool, leading to rapid wear. It is also highly reactive, which can cause chips to weld to the tool. To overcome this, you must use low cutting speeds, high feed rates, and a constant flow of high-pressure coolant. A rigid machine setup is also essential to prevent vibration and ensure accuracy.

Standard Machining's Titanium Solutions

Successfully machining medical titanium requires deep expertise. You need a manufacturing partner who understands the material's complexities and is equipped with the right technology and processes.

At Standard Machining, we specialize in high-precision CNC machining of titanium components for the medical industry. Our experienced team leverages advanced equipment to overcome machining challenges, delivering parts that meet the most stringent quality standards. We are committed to providing reliable solutions for your most critical medical device needs.

Conclusion

Medical grade titanium is a vital material in modern healthcare. Its unique blend of biocompatibility, strength, and corrosion resistance makes it ideal for life-saving and life-enhancing devices. Understanding its properties helps you choose the right material for your next medical application.

FAQs About Medical Grade Titanium

1. Is Medical Grade Titanium Magnetic?

No, medical grade titanium is non-ferromagnetic. This is a critical safety feature, as it means patients with titanium implants can safely undergo MRI (Magnetic Resonance Imaging) and CT (Computed Tomography) scans without risk or image distortion.

2. How Long Do Titanium Implants Last in The Body?

Titanium implants are designed to be permanent. Due to their exceptional corrosion resistance and biocompatibility, they can last for 20 years or more. Many implants function perfectly for the remainder of a patient's life without needing replacement.

3. Can The Body Reject a Titanium Implant?

True rejection of titanium is extremely rare. Because of its high biocompatibility and the protective oxide layer that forms on its surface, the human body does not trigger an immune response against it. Most implant "failures" are due to other factors, such as infection or mechanical issues, not a rejection of the material itself.

4. What Is The Main Difference Between Grade 5 and Grade 23 Titanium?

The key difference is purity. Grade 23 (Ti-6Al-4V ELI) is a higher-purity version of Grade 5. It has lower levels of oxygen, carbon, and iron. This makes Grade 23 more ductile and gives it superior fracture toughness, making it a safer choice for critical, long-term implants like dental roots.