PEEK vs. Metal: When to Choose High-Performance Plastics for Downhole Seals

Selecting the right material for harsh environments often comes down to a choice between PEEK vs. Metal. While metals like Inconel have long been the industry standard, high-performance plastics are now surging in popularity for downhole seals.

In modern oil and gas operations, the shift toward PEEK is driven by its unique ability to withstand corrosive chemicals and extreme pressures. Understanding the trade-offs in PEEK vs. Metal is essential for ensuring long-term tool reliability and preventing costly seal failures.

What is PEEK?

Polyetheretherketone, commonly known as PEEK, is a high-performance semi-crystalline thermoplastic. In the world of CNC machining, it is regarded as one of the most robust polymers available. Unlike standard plastics used in consumer goods, PEEK belongs to the polyaryletherketone (PAEK) family, engineered specifically for high-stress industrial applications.

The molecular structure of PEEK provides it with a unique combination of mechanical strength and thermal stability. It maintains its structural integrity even when exposed to high temperatures and aggressive fluids, making it a favorite for "hot-hole" environments in the energy sector.

Key Material Properties

PEEK is characterized by its high melting point of approximately 343°C (649°F). However, for downhole seals, the more critical metric is their continuous service temperature, which typically reaches up to 260°C (500°F). Beyond its thermal performance, PEEK is extremely hard and wear-resistant, often replacing metal components in bushings, bearings, and sealing systems.

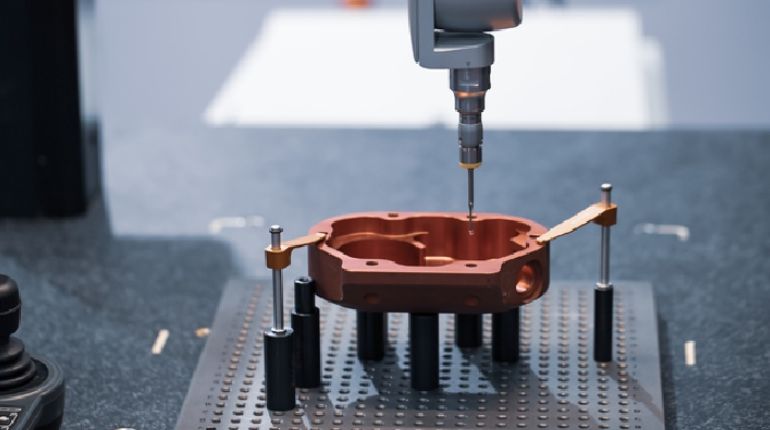

Why CNC Machining Matters

Because PEEK is a premium material, it is rarely injection-molded for critical downhole parts. Instead, it is CNC machined from extruded rods. Machining allows for the high precision and tight tolerances required for seals to seat properly. At Standard Machining, we understand that PEEK behaves differently than metal under a cutting tool; it requires specific speeds, feeds, and sharp geometry to avoid built-up heat that could distort the final part.

Comparing PEEK vs. Metal

When weighing PEEK vs. Metal, engineers must look beyond simple tensile strength. The decision usually hinges on how the material interacts with the specific chemistry and physical demands of the wellbore.

Chemical Resistance

One of the primary reasons to choose PEEK over metal is its immunity to corrosion. Downhole environments are often "sour," containing high concentrations of Hydrogen Sulfide (H₂S) and Carbon Dioxide (CO₂).

- Metal: Even high-grade stainless steels can suffer from stress corrosion cracking or pitting when exposed to sour gas. Specialized alloys like Inconel or Monel perform better but are significantly more expensive and difficult to machine.

- PEEK: This polymer is virtually inert. It does not rust, corrode, or degrade when exposed to the vast majority of oilfield chemicals, acids, and steam. This makes it the safer bet for long-term deployments in chemically aggressive wells.

Weight and Density

In deepwater or extended-reach drilling, the weight of the tool string is a major engineering constraint.

- Strength-to-Weight Ratio: PEEK has a density of approximately 1.32 g/cm³, while steel has a density of about 7.8 g/cm³. Replacing metal seal housings or backup rings with PEEK can significantly reduce the weight of downhole assemblies without compromising mechanical support.

Sealing Integrity

The physical "feel" of the material matters during installation.

- Compliance: Metal-to-metal seals require near-perfect surfaces and high seating forces to achieve a gas-tight seal. PEEK, while very hard for a plastic, has a modulus of elasticity that allows it to "conform" slightly to the mating metal surface. This allows it to create a reliable seal even if the borehole casing has minor scratches or irregularities.

Thermal Expansion

This is one area where the PEEK vs. Metal debate gets technical. Plastics generally have a higher Coefficient of Thermal Expansion (CTE) than metals.

- Predictability: As a tool goes deeper and temperatures rise, a PEEK seal will expand more than the metal housing surrounding it. Machinists and engineers must calculate these expansion rates precisely to ensure the seal doesn't "lock up" or crush itself at depth, while still maintaining a tight fit at the surface.

When to Choose Metal Seals

Despite the benefits of plastics, metal remains the king of "Extreme HPHT" (High Pressure, High Temperature) conditions.

Extreme High Pressures

In ultra-deepwater applications where pressures exceed 20,000 psi, PEEK may begin to "creep" or deform over time. Metal seals—specifically those made from beryllium copper or specialized stainless steels—provide the structural rigidity necessary to hold back these massive forces without changing shape.

Extreme Temperatures

If a well’s constant operating temperature exceeds 260 °C (500 °F), PEEK reaches its glass transition phase, where it begins to soften. In these "Ultra-HPHT" scenarios, metal seals are the only viable option, as they can maintain their mechanical properties well beyond the limits of any polymer.

Permanent Installations

For components intended to stay downhole for 20 to 30 years (such as permanent well completions), metal is often preferred for its fatigue life. While PEEK is durable, the long-term data on metal alloys in static environments is more extensive, giving operators a higher degree of "tried and true" confidence.

When to Choose PEEK Seals

For the majority of modern drilling operations, PEEK offers advantages that metal simply cannot match.

Sour Gas Environments

As mentioned earlier, the presence of H₂S is a "metal killer." If your project involves a sour well, using PEEK for seals and backup rings is one of the most effective ways to prevent catastrophic hydrogen embrittlement.

Electrical Insulation

Modern downhole tools are "smart," filled with sensors and electronics used for Logging While Drilling (LWD).

- Dielectric Properties: Metal is a conductor; PEEK is an insulator. When a seal needs to separate electronic components or prevent electrical interference, PEEK is the natural choice. It allows for the passage of signals while maintaining a high-pressure barrier.

Reduced Friction Requirements

Metal-on-metal contact can lead to "galling"—a form of wear caused by adhesion between sliding surfaces. PEEK has a low coefficient of friction and is naturally self-lubricating. In moving seal assemblies, such as those found in hydraulic actuators or valves, PEEK components reduce the risk of the tool seizing up.

Machining PEEK for Downhole Success

At Standard Machining, we know that a great material is only as good as its execution. Machining PEEK is a specialized skill that differs greatly from machining aluminum or steel.

Stress Relieving and Annealing

PEEK builds up internal stresses during the extrusion process and during heavy machining. If these stresses aren't managed, the seal can warp or "relax" after it leaves the machine shop, falling out of tolerance. We utilize intermediate annealing cycles—heating the material in a controlled oven—to stabilize the plastic and ensure the final dimensions remain true.

Tooling Selection

Standard carbide tools used for metal can sometimes be too blunt for PEEK, causing the material to smear rather than cut. We use extremely sharp, polished-flute cutting tools to achieve the "mirror finish" required for high-pressure sealing surfaces.

Tolerance Control

In the oilfield, a "close enough" fit is a recipe for a blowout. We maintain tolerances as tight as ±0.005 mm on critical seal diameters. Achieving this in a polymer requires climate-controlled machining environments and a deep understanding of how the material reacts to tool pressure.

Conclusion

When evaluating PEEK vs. Metal for your downhole applications, there is no one-size-fits-all answer. While metal offers unmatched strength at extreme temperatures, PEEK provides superior chemical resistance and sealing flexibility that can significantly extend the life of your equipment.

At Standard Machining, we specialize in the precision CNC machining of both high-performance plastics and hardened alloys. Contact our engineering team today to discuss your project requirements and let us help you manufacture the perfect seal for your specific downhole environment.