The Best Surface Finishing For Bronze: Chemical Polishing Explained

Bronze is an incredibly versatile metal, used in a variety of applications from art and sculpture to industrial components. To ensure the highest quality finish, it's important to select the right surface finishing method.

Chemical polishing is widely regarded as one of the best methods for treating bronze and achieving superior results. In this article, we'll explain why chemical polishing is such an effective surface finishing solution for bronze.

With its unique combination of strength and malleability, bronze has been used by humans for centuries to create everything from jewelry and sculptures to complex machinery parts. In order for these bronze objects to function properly or look their best, it's essential that they have an attractive, durable finish.

Chemical polishing is a great choice when you need a high-quality surface finish on your bronze pieces. Keep reading to learn more about how this process works and why it's so effective!

What Is Chemical Polishing?

Chemical polishing is a machining technique that can be used to finish the surface of bronze and other metals.

It is an effective way to reduce surface roughness, improve dimensional accuracy, and create a uniform appearance.

Chemical polishing works by using acid or alkaline solutions to remove surface irregularities and produce a smooth, glossy finish.

The process can also be used to remove burrs, pits, or other imperfections from the metal's surface.

The chemical polishing process has several advantages over traditional mechanical polishing techniques.

It is often faster than other methods, and it does not generate heat which could damage the material being polished.

Additionally, chemical polishing does not require specialized tools or abrasive materials, making it more cost effective in many cases.

With careful attention to detail and proper setup of the process, chemical polishing can result in shiny surfaces with minimal effort.

Advantages Of Chemical Polishing

Chemical polishing is an excellent surface finishing option for bronze that has many advantages.

It is cost effective, as it requires only one step to complete the process and the chemicals used are reasonably priced.

Additionally, chemical polished bronze has a high corrosion resistance, making it ideal for items that will be exposed to harsh conditions such as moisture and salt air.

The results of chemical polishing are also impressive; the surface will be smooth with no sharp edges and a brilliant shine that can last for years.

Furthermore, chemical polishing can be done on a variety of metal alloys, including bronze. This makes it an ideal choice for those looking to save time and money while ensuring their item looks its best.

Those who opt for chemical polishing of their bronze piece can rest assured knowing they have made a great decision that will provide long lasting results.

Disadvantages Of Chemical Polishing

Chemical polishing is a popular choice for surface finishing bronze due to its capability of creating a mirror-like finish. However, there are some cost considerations and environmental impacts to consider before selecting it as the best option.

One of the biggest drawbacks of chemical polishing is its expense. It is often more costly than other mechanical processes such as sanding or buffing. Additionally, it requires specialized equipment and well-trained personnel, which can add to costs. Furthermore, because chemicals used in this process are corrosive, disposal fees can be high.

On top of the financial implications, there are also environmental concerns associated with chemical polishing. Since many chemicals used in the process are hazardous they can cause air and water contamination if not disposed of properly. Therefore, extra precautions must be taken when using this method to avoid long-term damage to the environment.

Despite these potential negatives, chemical polishing is still a viable option for finishing bronze surfaces due its impressive results and ability to create unique shapes and patterns that would otherwise be impossible with traditional methods like sanding or buffing. Therefore, it should be considered carefully when deciding on a suitable surface finishing approach for any project involving bronze materials.

When Is Chemical Polishing Recommended?

Chemical polishing is like a shining beacon of hope for bronze surfaces. It can provide a smooth, lustrous finish that will have onlookers practically drooling. When it comes to surface preparations, chemical polishing offers an ideal solution:

- Cost-effective - Chemical polishing requires minimal investment in materials and labor.

- Environmentally friendly - This process does not require the use of harsh chemicals or solvents.

- Odorless - Unlike other finishing techniques, chemical polishing does not emit unpleasant odors.

- Time saving - Chemical polishing can be completed quickly and efficiently.

Chemical polishing offers many advantages over other methods because it yields superior results with minimal effort. Its ability to produce a bright, gleaming surface with virtually no prep work makes it a great choice for those looking to achieve optimal results in a short amount of time. Plus, its cost effectiveness makes it an excellent option for any budget-minded individual or organization.

In short, chemical polishing is often the best choice when it comes to giving bronze surfaces their desired sheen and shine.

The Chemical Polishing Process

Chemical polishing is a process that utilizes the chemical properties of a material to improve its surface properties. This method is recommended when traditional methods such as sanding and grinding are insufficient for achieving the desired surface finish.

Chemical polishing is often used on materials such as bronze, where it can provide an additional level of surface smoothness and shine.

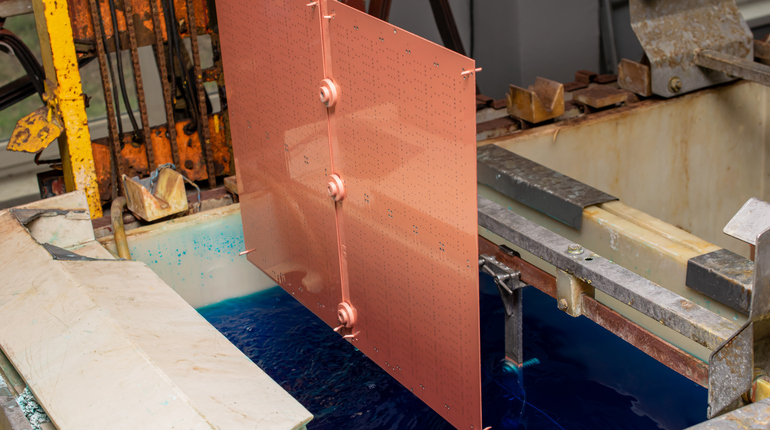

The chemical polishing process begins by cleaning the bronze surface with a solvent to remove any contaminants that may be present. The next step is to submerge the object in a mild acid solution for a specific amount of time, which helps break down any impurities on the surface.

Afterward, the object is rinsed off with water and dried in order to prevent further oxidation or corrosion. Finally, the object is subjected to a buffing wheel or cloth in order to achieve the desired level of polishing and shine.

By following these steps, one can achieve a beautiful finish on any bronze object.

Choosing The Right Chemical Polishing Solution

When it comes to selecting a polishing solution for bronze, there are a few things to consider.

We need to think about the type of chemical, the concentration, and the buffing speed.

It's important to understand the properties of the polishing chemicals so we can get the best results.

The type of chemical can have a major effect on the outcome of the polishing process.

Additionally, we need to consider the concentration and buffing speed, as they can affect the final look of the piece.

Optimizing polishing results requires careful balancing between the chemical, concentration and buffing speed to get the desired result.

Selecting A Polishing Solution

When it comes to selecting the right chemical polishing solution for your bronze surface, it’s important to consider several factors.

Preparation techniques such as grinding, sanding, and tumbling are key to ensuring a smooth finish. Proper surface preparation also involves removing rust or other corrosion that may have built up on the metal.

The selection of the right chemical polishing solution depends on the type of metal being polished and the desired end result. When choosing a polishing solution for bronze, look for one that is specifically formulated for use on non-ferrous metals. This will help you achieve a high-quality shine without damaging the metal surface with harsh chemicals.

Additionally, be sure to follow all safety precautions when working with chemical polishing solutions and always wear protective gear such as gloves and eye protection. With careful selection and proper preparation, you can ensure your bronze surfaces get the best finish possible.

Considerations For Polishing Chemicals

When it comes to chemical safety, always be sure to follow the instructions on the polishing solution’s container and wear protective gear such as gloves and eyewear.

It's also important to take into account the texture of the surface you are polishing. If the surface is rough and uneven, a polishing solution with mild abrasion may be necessary to achieve a smooth finish.

On the other hand, if the surface is already relatively smooth, then a gentler polishing solution may be best.

Ultimately, choosing the right chemical polishing solution for your bronze surface not only ensures you get a high-quality shine without damaging the metal but also allows you to achieve your desired end result safely.

Optimizing Polishing Results

Once you've chosen the right chemical polishing solution for your bronze surface, it's time to start preparing the surface for polishing.

This includes cleaning off any dirt or debris, as well as removing oxidation and patina that may be present.

Proper surface preparation is key to optimizing your results, so make sure you take the necessary steps before you begin polishing.

Polishing techniques also play a role in achieving optimal results.

Whether you're using a polisher or manual buffing tools, it's important to use gentle circular motions and avoid applying too much pressure on the bronze surface.

Being mindful of these details will help ensure that you get the best possible shine without damaging the metal.

Common Mistakes To Avoid

The process of chemical polishing bronze is a delicate balance between art and science. It requires an experienced technician to ensure that the surface is smooth, glossy, and free from corrosion. With the right technique and materials, however, it can be a relatively inexpensive way to restore your bronze piece to its original beauty.

When it comes to preventing corrosion and determining costs for chemical polishing bronze, there are some common mistakes you should avoid:

- Not inspecting the item prior to restoration

- Not using the correct tools or materials

- Not considering environmental factors such as humidity or temperature

- Not understanding the cost of repairs in comparison to value of item.

Chemical polishing bronze may seem intimidating at first but with proper research, knowledge, and guidance from professionals you can get beautiful results with minimal expense. By avoiding these common mistakes you can master the art of chemical polishing while ensuring your bronze pieces look their best.

Tips For Achieving The Best Results

Chemical polishing is one of the best surface finishing techniques for bronze. It ensures a smooth finish that's resistant to scratches and dents, while also providing superior corrosion protection.

To achieve the best results, it's important to understand the basics of chemical polishing so that you can be sure your project will stand up to durability testing.

It's important to take into account the type of bronze you're working with before beginning any chemical polishing process. Different alloys require different treatments and storage solutions. When in doubt, consult a professional or do some research on what methods are most effective for your particular alloy.

After ensuring that you have all the materials needed for the job, make sure you wear proper safety equipment and follow instructions closely. With careful attention to detail and some patience, you'll be able to achieve a beautiful finish that will last for years to come.

Conclusion

Chemical polishing is an effective surface finishing solution for bronze. It provides a smooth, uniform finish that is both aesthetically pleasing and durable.

To get the best results from chemical polishing, it's important to choose the right chemical solution and be mindful of common mistakes.

For example, a bronze sculpture in a public park was recently restored using chemical polishing. The end result was stunning; it brought a new energy to the park and attracted many visitors.

Chemical polishing can help bring your bronze projects to life in the same way!