Top 7 Finishes for Your Aluminum Extrusion Parts

Choosing the right finish for aluminum parts is a critical decision. This guide covers the top 7 finishes for your aluminum extrusion parts, helping you select the best option for your project's needs.

We will explore each finishing process in detail. You will learn about their unique benefits, ideal applications, and key considerations. This will help you make a fully informed choice.

Why Finish Aluminum Extrusions?

Raw aluminum naturally forms a protective oxide layer. However, this layer is very thin. Professional finishing is often necessary.

Finishes provide significant benefits. They enhance corrosion resistance and durability. They also improve the part's appearance. A proper finish ensures your parts perform well and last long.

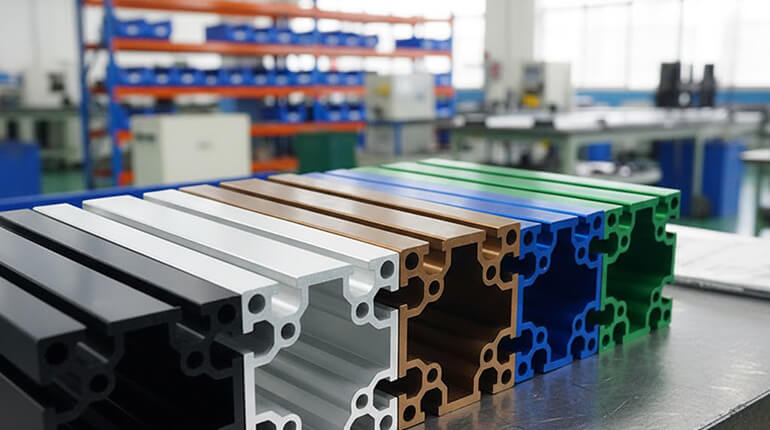

Top 7 Finishes for Aluminum

Several finishing options are available. Each offers a unique combination of protection, appearance, and cost. Here are the seven most common types.

1. Anodizing

Anodizing is an electrochemical process. It creates a thick, stable oxide layer on the aluminum's surface. This layer is integrated with the underlying metal.

This process greatly boosts durability. It provides excellent resistance to corrosion and abrasion. The porous surface can also be dyed with various colors. Anodized finishes are UV resistant and will not chip or peel.

2. Powder Coating

Powder coating involves applying a dry, powdered polymer. The powder is applied electrostatically to the grounded part. The part is then cured in an oven.

This method creates a thick, hard finish. It is more durable than conventional liquid paint. Powder coating offers a vast range of colors and textures. It is also environmentally friendly, with near-zero volatile organic compounds (VOCs).

3. Liquid Painting

Liquid painting is a traditional finishing method. It involves spraying wet paint, such as acrylic or polyester, onto the part. This provides a high-quality decorative finish.

The main advantage is the unlimited color selection. Custom color matching is very precise. Liquid paint is ideal for parts that cannot be heated. It is also great for achieving very thin finish layers.

4. Mechanical Finishes

Mechanical finishes physically alter the aluminum's surface. This is done through processes like grinding, polishing, or blasting. They create a specific look or texture.

Common effects include a brushed, satin, or mirror-like finish. Sandblasting creates a uniform matte texture. These finishes are typically used for aesthetic purposes. They are often a pre-treatment before other finishing processes.

5. Chemical Finishes

Chemical finishes use chemical reactions to treat the surface. The most common type is a chemical conversion coating. It creates a thin, protective film.

These coatings enhance corrosion resistance. They also provide an excellent base for paint adhesion. Etching is another chemical finish. It cleans the surface and creates a soft, matte appearance.

6. Bright Dipping

Bright dipping is a chemical brightening process. The aluminum part is dipped into a heated solution. This solution smooths out microscopic surface imperfections.

The result is a highly reflective, mirror-like finish. It is often used before anodizing to achieve a specular look. This process is popular for decorative trim and cosmetic parts.

7. Sublimation

Sublimation creates highly decorative, photo-realistic finishes. You can achieve complex patterns like wood grain or stone textures. This process adds significant aesthetic value.

First, a base powder coat is applied. Then, a film with the desired pattern is wrapped around the part. Heat and pressure transfer the pattern's ink into the base coat. The result is beautiful, durable, and long-lasting.

How to Choose The Right Finish?

Selecting the best finish depends on several factors. You must consider your project's specific requirements.

- Environment: Will the part be used indoors or outdoors? Will it face moisture or chemicals?

- Durability: Does it need to resist scratches, impact, or abrasion?

- Appearance: What color, gloss level, and texture do you want?

- Cost: What is your budget for the finishing process?

Answering these questions will guide you to the perfect choice.

Comparing Top Aluminum Finishes

| Feature | Anodizing | Powder Coating | Liquid Painting |

| Durability | Excellent | Excellent | Good |

| Corrosion Resistance | Excellent | Very Good | Good |

| Color Options | Good | Excellent | Unlimited |

| Cost | Moderate | Moderate | Moderate to High |

| Best For | High-wear parts, electronics | Outdoor use, industrial parts | Custom colors, complex shapes |

Applications of Aluminum Finishes

Different industries prefer specific finishes. The choice depends on performance and aesthetic needs.

- Architectural: Anodizing and powder coating are used for window frames and panels.

- Automotive: Bright dipping and anodizing are used for decorative trim.

- Electronics: Anodizing is popular for laptop casings and device bodies.

- Consumer Goods: Powder coating is used on bicycle frames and outdoor furniture.

Get Custom Finishes With Standard Machining

Choosing the right finish is just as important as the design itself. The best choice protects your part and enhances its value. Standard Machining can help you with this critical step.

We offer a wide range of finishing services for CNC machined parts. Our experts will guide you to the perfect solution. We ensure your parts meet all functional and aesthetic requirements.

Contact us today to discuss your project and get a free quote.

Conclusion

The right finish improves your aluminum extrusion's durability, corrosion resistance, and appearance. By understanding the options from anodizing to sublimation, you can select the ideal process that aligns with your project's goals and budget.

FAQs on Aluminum Finishes

1. What is The Most Durable Finish for Aluminum?

Type III hardcoat anodizing is one of the most durable finishes. It creates an extremely hard, abrasion-resistant ceramic-like layer. High-performance powder coatings also offer excellent durability and impact resistance, making them ideal for demanding environments.

2. Is Powder Coating Better Than Painting?

For durability, powder coating is generally superior to liquid paint. It creates a thicker, more uniform finish that is highly resistant to chipping, scratching, and fading. However, liquid paint offers more precise color-matching capabilities and is better for parts that cannot be oven-cured.

3. Can You Finish Aluminum to Look Like Stainless Steel?

Yes. You can achieve a stainless steel look through several methods. A clear anodized finish on a mechanically brushed or satin-finished aluminum part closely mimics the appearance of stainless steel. Certain shades of silver powder coating can also produce a similar effect.

4. What is a Pre-Treatment for Aluminum Finishing?

Pre-treatment is a critical first step for any finishing process. It involves thoroughly cleaning the aluminum surface to remove oils, dirt, and oxides. Common steps include degreasing, etching with an acid or alkaline solution, and sometimes applying a chemical conversion coating to improve adhesion and corrosion resistance.