What Is Burnishing And How Does It Improve Tungsten Steel?

Burnishing is a metalworking technique that has been used to improve the durability and longevity of tungsten steel for centuries. Not only does it help to make tungsten steel stronger, but it can also enhance the beauty of the material.

Whether you're a metalworker or hobbyist looking to get started with burnishing, this article will provide you with all the facts you need to know about this process.

Burnishing is an important part of working with tungsten steel and requires an understanding of certain techniques. It's important to understand what burnishing is, how it works, and why it's so effective in improving the strength and appearance of tungsten steel.

We'll explore all these topics in detail in this article so that you can gain a better understanding of how burnishing works and why it's such an essential part of metalworking with tungsten steel.

What Is Burnishing?

Burnishing is a process used to improve the surface of tungsten steel by polishing and compressing it. It is used in many industries that require precise, accurate parts such as aerospace, automotive, and medical devices.

The process involves using mechanical force to compress the material and smooth out any imperfections on its surface. This creates a smoother surface on the tungsten steel which can then be heat treated to further increase its strength and durability.

Burnishing can be done manually or with machines, depending on the size and complexity of the part being worked on. Manual burnishing produces a higher quality finish than machine burnishing as it allows more control over the depth and intensity of pressure applied to the surface of the tungsten steel.

As a result, it improves the wear-resistance of the material which makes it better suited for use in high-stress applications such as aerospace components or medical implants.

The Benefits Of Burnishing

Burnishing is a process of compressing and hardening the surface of tungsten steel. It's done by applying pressure to the surface with a tool such as a roller, ball or file. This causes the metal to become harder, denser and smoother, providing greater protection against wear and tear.

The strengthening effects of burnishing are significant as it increases the hardness of tungsten steel up to three times its original value. This means it can withstand higher levels of stress before breaking or cracking.

The surface hardening effect of burnishing also makes tungsten steel more resistant to corrosion and abrasion. The increased resistance to wear helps preserve the material for longer periods of time, making it ideal for use in high-stress applications such as medical instruments or industrial tools.

Additionally, burnishing results in an aesthetically pleasing finish which is often desired for decorative purposes. Overall, burnishing improves tungsten steel by increasing its strength, reducing wear and tear and providing an attractive finish.

The Tools Used To Burnish Tungsten Steel

Burnishing tungsten steel is a process that helps to improve its strength, durability, and resistance.

It can be done with a few different tools, including a grinding wheel, sandpaper, and a polishing cloth.

The grinding wheel is used to remove any imperfections on the steel surface.

Sandpaper is then used to smooth out the surface, while the polishing cloth is used to give the steel a glossy finish.

All of these tools help to improve the tungsten steel's overall quality and performance.

Grinding Wheel

The grinding wheel is an essential tool for burnishing tungsten steel. It's a major part of the surface preparation process, as it's responsible for removing any blemishes or imperfections that could impede the metal's ability to absorb the finishing material.

Abrasive selection is key when it comes to getting the right outcome. The right combination of grit, hardness and bond will ensure that only minimal material is removed and that the steel isn't damaged in the process.

Burnishing with a grinding wheel can result in a brilliant shine, smoother surface and greater overall strength – making it an invaluable tool for anyone looking to achieve top quality results.

With proper selection and use of grinding wheels, you'll be able to take your tungsten steel projects to the next level.

Sandpaper

Sandpaper is another great tool for burnishing tungsten steel. With the right grit size and polishing techniques, it can be used to create a smooth and glossy finish.

Sandpaper is also more flexible than grinding wheels, making it easier to work in those hard-to-reach places. Plus, with its wide range of grits, you'll be able to find the best one for whatever project you're working on.

You can even get creative and combine different grits to achieve a unique result. Using sandpaper is a great way to get that perfect look you're after with your tungsten steel projects.

It's easy to use and there's no need for expensive machinery or tools – just some basic sandpaper and elbow grease! With careful selection and proper technique, you'll be able to take your metalworking projects up a notch.

Polishing Cloth

Polishing cloth is an essential tool for fine tuning your tungsten steel projects.

Not only is this material soft and gentle, it's also wear resistant, so it won't damage the surface of your metal.

Plus, you can use it to finish off a project without having to invest in expensive tools.

It's a great way to get that perfect sheen and make sure all your hard work shines through.

Using a polishing cloth can really take your projects up a notch.

You can use it to buff out any rough patches from sanding or grinding and achieve that smooth, glossy look without compromising the integrity of your tungsten steel.

With its easy application and affordable price, this is one tool you'll want to keep handy whenever you're working with metal.

The Process Of Burnishing Tungsten Steel

Burnishing is a polishing technique that can be applied to tungsten steel to improve its surface texture. It involves using a hard, smooth tool to rub or roll over the steel’s surface. This rubbing action compresses and flattens the metal’s microscopic imperfections, leaving behind a smoother, more polished result.

Burnishing can also reduce friction and wear on surfaces and increase durability of tungsten steel products. Here are some of the benefits of burnishing tungsten steel:

- Increased durability and longevity

- Improved resistance to wear and tear

- Enhanced surface finish for aesthetic purposes

By applying the burnishing process to tungsten steel products, it is possible to achieve a higher quality end product that is sure to impress. The improved surface texture will make any product look more refined and professional. The increased durability will ensure that these products last longer and require less maintenance in the long run.

The Different Burnishing Techniques

Burnishing is a surface treatment that can dramatically improve the properties of tungsten steel. Through various polishing methods, burnishing can refine the surfaces of tungsten steel and make them smoother, more durable, and more resistant to wear and tear.

The process involves using a hard tool to apply pressure to the metal surface, which creates indentations or scratches that are subsequently filled with lubricant. This results in a much smoother surface with improved resistance to corrosion and higher fatigue strength.

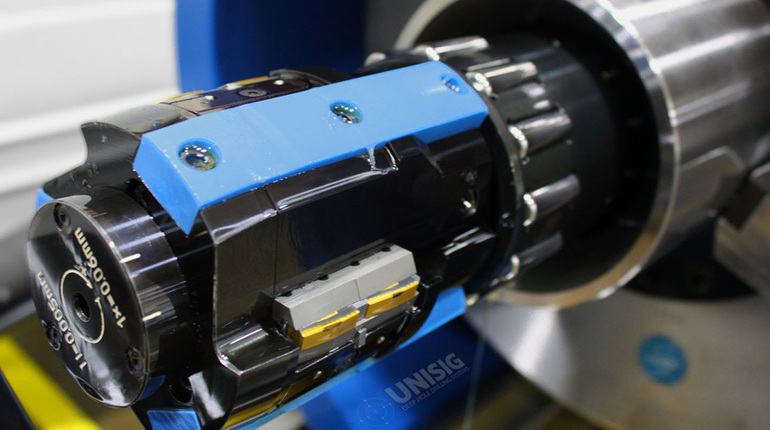

The different burnishing techniques available for tungsten steel include rotary burnishing, linear burnishing, roller burnishing, and vibratory burnishing. Rotary burnishing uses a rotating tool that interacts with the metal’s surface to create an even finish. Linear burnishing uses a single-point cutting tool that moves along the material’s surface at a constant rate.

Roller burnishing employs either an adjustable or stationary roller to compress the metal’s grain structure, resulting in increased hardness without removing material from the surface. Lastly, vibratory burnishing utilizes multiple tools that vibrate against the metal’s surface in order to achieve uniformity and smoothness of finish.

All of these methods can be used on tungsten steel surfaces to improve their performance characteristics as well as their appearance.

Burnishing And Corrosion Resistance

Burnishing is a process used to improve the surface finish of tungsten steel by compressing the metal and creating a smoother, more durable surface.

This process increases the hardness and corrosion resistance of the steel, making it more durable and able to withstand wear and tear. It also makes the material more resistant to corrosive agents, protecting it from rust and other forms of oxidation.

With the increased surface hardness, burnishing also makes the material more resistant to scratches, dents, and other types of damage.

Burnishing Process

Burnishing is a process that can dramatically improve the corrosion resistance of tungsten steel. It involves using either laser etching or diamond polishing to impart a smooth finish to the surface.

This creates a tightly packed, hard layer of metal on the surface, making it difficult for corrosion-causing agents to penetrate and cause damage. To ensure that this finish remains intact, it's important to regularly inspect and recoat any exposed areas as needed.

This helps to extend the life of the tungsten steel and keep it looking its best. With a burnished finish, you can enjoy years of worry-free use from your tungsten steel products with minimal maintenance.

Corrosion Resistance

Burnishing improves the corrosion resistance of tungsten steel, but with any metal, it's important to keep an eye on exposed areas for corrosion.

The process of surface hardening can provide an extra layer of protection from corrosion-causing agents.

By using a combination of case hardening and burnishing, you can create a harder surface that will last longer and stand up better against the elements.

This makes it much easier to maintain your tungsten steel products over time.

Plus, with regular maintenance and recoating as needed, you can ensure that your tungsten steel looks good and performs well for years to come.

Burnishing And Aesthetic Appeal

Burnishing is a process of polishing that is used primarily on tungsten steel. It involves using specific tools to create a smooth, shiny surface which enhances the aesthetic appeal of the material.

Burnishing helps to improve the wear resistance and durability of tungsten steel, adding greater strength and longevity to any product crafted from it. The burnishing process also creates interesting knotting patterns, resulting in an eye-catching texture that can be further enhanced with additional polishing effects.

The result is a durable and aesthetically pleasing material that stands out from other metals and gives your project a unique look. Burnishing provides excellent protection against corrosion while enhancing the appeal of tungsten steel products.

No matter what type of project you are working on, burnishing can provide you with excellent results that will truly stand out from the crowd.

Burnishing And Durability

Burnishing is a finishing technique that can improve the look and durability of tungsten steel. This process involves pressing or rolling a hard, smooth object over the surface of the material to create an even, polished finish.

By burnishing the surface of tungsten steel, it not only becomes aesthetically appealing but also increases its wear resistance and machine compatibility. The burnishing process begins by applying a lubricant to the tungsten steel and then using pressure to polish the surface. The amount of pressure applied is dependent on the desired outcome.

To increase wear resistance, more pressure should be used as this creates a smoother surface which resists abrasion better. Increasing machine compatibility requires less pressure as this leaves a rougher surface which allows for better adhesion of coatings and paints. The benefits of burnishing tungsten steel include:

- Increased wear resistance

- Improved aesthetic appeal

- Enhanced machine compatibility

Burnishing is an effective way to improve both the look and longevity of tungsten steel without sacrificing its inherent properties such as strength and rigidity. For these reasons, it is becoming increasingly popular among craftspeople and industrial manufacturers alike who are looking for ways to make their products last longer while still looking good.

Conclusion

In conclusion, burnishing can be a great way to improve the durability and aesthetic appeal of tungsten steel. It's a simple process that can yield impressive results, and with the right tools, it can be done quickly and easily.

According to research, burnishing on tungsten steel increases its surface hardness by up to 50%, making it an invaluable technique for strengthening and protecting this versatile material.

I highly recommend researching what burnishing techniques are available for your specific application in order to get the most out of your tungsten steel project.